In industrial workshops, there are many types of dust collectors, each with its advantages and disadvantages. Common dust collectors include cartridge dust collectors, bag dust collectors and cyclone dust collectors. In contrast, electrostatic precipitators and wet precipitators are less used due to their high investment cost and limited applicability. Although electrostatic precipitator has high efficiency, its economy is not high. Wet dust collectors are more suitable for handling wet, sticky or hazardous dust. Therefore, the selection of appropriate dust collector is very important to improve air quality and production efficiency.

What is a Cyclone Filter?

Cyclone filters are widely used to control particulate emissions in the air. Their simple structure, ease of installation, and straightforward maintenance make them popular in many grain processing facilities, including grain cleaning, drying, seed production, storage, and feed processing. These devices have no moving parts, resulting in low operational costs and reduced failure rates, efficiently managing the dust generated during grain production.

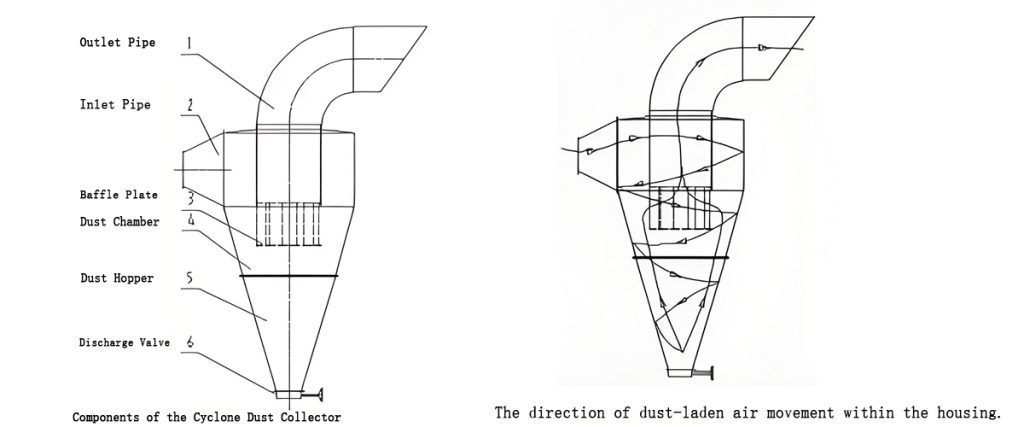

Cyclone dust collector is a dry dust removal device, which can effectively capture particles with particle size between 5 and 10 microns. Its working principle is that the dusty air enters the dust collector through the fan and rotates in a spiral shape in the shell. The centrifugal force and friction force separate the dust from the airflow, make it adhere to the wall, and finally sink to the bottom under the action of gravity.

In addition, the enhanced design integrates annular baffles in the housing. After preliminary treatment, the uncollected fine particles will collide with these baffles, further separate under the action of gravity and friction, and finally settle the dust into the designated chamber. This design is not only compact and space saving, but also significantly improves the dust removal efficiency.

Advantages of Cyclone Dust Collectors

1. Simple structure, low operation cost: the cyclone dust collector has no moving parts and vulnerable parts, low operation cost and low failure rate. The design can effectively remove dust and is easy to manufacture, install and maintain.

2. Efficient dust treatment: cyclone is a dry dust removal system, which can effectively recover valuable dust. The dust accumulated at the bottom under the action of gravity can be easily discharged through the discharge valve and sent to the collection tank for treatment.

3. Parallel operation capacity: the cyclone can be used in parallel to handle large air volume. During operation, air enters at a high tangential speed, usually 12 to 25 m/s, to ensure uniform air flow and improve dust removal efficiency without increasing resistance.

4. High temperature resistance: the cyclone dust collector is made of carbon steel and can withstand high temperatures of more than 400 ° C. Under special conditions, the use of high temperature resistant materials can further improve its high temperature resistance.

Disadvantages of Cyclone Separators

1. Low efficiency in handling small particles: the cyclone separator is invalid for dust particles smaller than 5 microns or containing moisture and viscosity. When the dusty air enters the dust remover, the centrifugal force may not be able to effectively separate these fine and wet particles, resulting in poor filtering effect.

2. Easy to wear: the rotating movement of the gas will cause wear on the inner surface of the dust collector. The continuous impact of dust particles will increase the risk of damage over time.

Working Principle and Structural Design

Working Principle

The cyclone dust collector is composed of a feed pipe, a discharge pipe, a dust collecting chamber, a baffle, a dust collecting hopper and a discharge valve. Its simple structure, easy to manufacture, install and maintain, is an ideal choice for grain processing. When the dusty air flows through the dust collector at a speed of about 12-25 M/s, the centrifugal force acting on the dust particles can reach 5 to 2500 times the gravity. This makes it more efficient than the traditional gravity settling chamber. The baffle is added to further separate the dust particles through collision, so as to improve the efficiency.

Structural Design of Key Components

1.Inlet Pipe: The inlet pipe directs the airflow into the cyclone collector. It connects the fan to the dust collector housing. Tangential inlets are common, with angles typically set at 45°, 120°, 180°, or 270°. The efficiency of the cyclone collector depends on the inlet area and airflow. A smaller inlet area increases the tangential velocity, enhancing dust handling.

2.Outlet Pipe: The outlet pipe expels the treated air. As the air spirals to the bottom, it creates an upward internal vortex, allowing for smooth discharge through the outlet. The height and cross-sectional area of the outlet directly affect resistance and dust collection efficiency.

3.Baffle Plates: Baffle plates inside the collector facilitate additional dust separation. As air flows, larger, heavier dust particles settle into the hopper, while lighter particles collide with the baffles and are trapped, falling into the collection bin.

4.Dust Chamber: The design of the dust chamber minimizes airflow disruptions. The chamber is cylindrical and should be taller than the inlet to ensure effective dust removal. Dust falls into the hopper under gravity, where it accumulates for easy disposal.

5.Dust Hopper: Typically cone-shaped, the hopper directs the main airflow downward, enhancing the spiral motion of the dust-laden air. The hopper’s angle should exceed 60° to facilitate dust discharge.

6.Discharge Valve: The discharge valve is essential for removing accumulated dust. It should be designed for safety and ease of use, ensuring a tight seal to prevent air leakage, which can significantly impact efficiency.

Design and Application Effectiveness

The diameter of cyclone dust collector will affect its efficiency. The smaller the diameter, the smaller the rotating radius, and the greater the centrifugal force, so as to improve the dust removal efficiency. However, if the diameter is too small, the dust particles may collide with the shell, thus reducing the dust removal efficiency. In general, the optimal diameter range is 800 mm to 2500 mm. Other factors, such as particle size, viscosity, and airflow velocity, also affect performance. The efficiency of traditional cyclone is between 60% and 75%. Enhanced design (such as baffle) improves efficiency by increasing the surface area of particle collision, so as to capture more untreated dust particles.

In a word, cyclone stands out in various industrial applications, especially in grain processing environment, because of its high efficiency, simplicity and adaptability.

For more information on cyclone separators and how they can benefit your operations, please contact us. We are here to help you find the best solutions for your dust collection needs!