1. Problems Identified

Since 2020, Plant A, a dry-process cement production line, has frequently experienced several issues. These issues included clumping inside the cement silos, difficulty extracting cement from the silos, and material buildup during bulk train loading. The plant implemented countermeasures such as cleaning the silos, reducing the moisture content of mill feed materials, and using vibrating screens. These actions alleviated the cement shipment difficulties but did not provide a complete solution.

Plant A operates a cement kiln line. Its cement grinding system uses a combined (closed-circuit) process with a roller press and a ball mill. The clumping and blockage problem primarily occurred during the shipment of the P·O 52.5 cement type. This cement uses slag and limestone as mixed materials, and desulfurized gypsum as a retarder. The desulfurized gypsum contained 18.8% crystalline water and 40.6% SO₃. The cement production quality control targets were: 45 μm sieve residue (7 ± 2)%, specific surface area (340 ± 10) m²/kg, and SO₃ content (2.5 ± 0.2)%.

2. Investigation and Testing

2.1. Clumping Situation and Experimental Testing

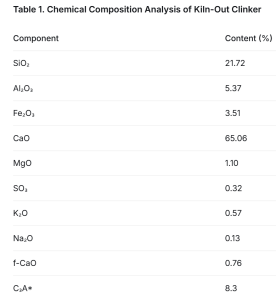

The most recent incident occurred in Silo 3, which stored P·O 52.5 cement. Lumps of cement blocked the discharge outlet, hindering material flow. Workers cleared the blockage using high-pressure air and by manually removing large clumps. Subsequently, no further blockages or flow issues occurred for one week. Notably, six months prior to this blockage, a vibrating screen had been installed at the silo inlet. Figure 1 shows the lumpy cement particles screened out at the inlet. The large lumps had already gained considerable strength, as they did not break when dropped from a height of 0.5 meters. However, smaller particles could be crushed by hand. Figure 2 shows hardened clumps removed during a previous clearing operation. This cement had hardened and gained strength, also largely resisting breakage from a 0.5-meter drop. Furthermore, clumped material was observed in the cement during the loading and shipment process from Silo 3.

We weighed the sampled cement extracted from the silo and the material retained on a 0.9 mm square-mesh sieve. The mass proportion of balled/clumped material was 10.5%. Tests showed the average moisture content of this balled/clumped material was 1.15%, and the average moisture of the screened slag lumps (Figure 1) was 0.97%. These values significantly exceeded the control limit of 0.6%. We dry-brushed and crushed the balled material on the 0.9 mm sieve. The crushed material had a specific surface area of 405 m²/kg, about 60 m²/kg higher than the average. This indicates a much higher content of fine powder (<3 μm particles) in the balled material compared to the average input cement. Therefore, agglomeration and balling likely occur more readily in the fine cement powder. This can also be interpreted as the fine powder being more prone to pre-hydration. After unloading, about 1-2 tons of residual cement remained stuck near the discharge outlet inside the returned railway tankers. This cement showed adhesion and was easily crumbled by hand. Its average moisture content was 0.96%, similar to the excessive moisture found in the lumps and balls.

2.2. Cause Investigation and Verification

Based on the clearly abnormal moisture in the balls and lumps, we initially deduced the cause. We suspected that small cement particles underwent hydration nucleation when exposed to (or absorbing) water under high temperatures. These then gradually grew into clumps and lumps during storage. Consequently, we further investigated cement moisture, mill outlet temperature, and particle size distribution.

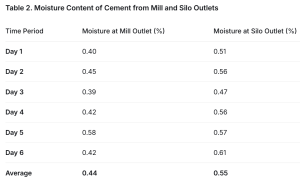

We continuously monitored and recorded the moisture content of the P·O 52.5 cement entering the silo. Table 2 shows the results. The average moisture was 0.44% at the mill outlet and 0.55% at the silo outlet. In contrast, the average moisture of the balled and lumpy cement was 1.06%. This indicates the cement absorbed moisture during storage, increasing the overall moisture by 0.11%. The moisture in the balled/lumpy cement increased by 0.62%.

We also tracked the temperature of the gas at the mill outlet during P·O 52.5 production (Table 3). The gas temperature was 5–10 °C lower than the powder temperature. The cement temperature was approximately 110 °C. This high temperature provided the necessary condition for the dehydration of desulfurized gypsum during storage. The crystalline water released from the gypsum converted into free water, which was then absorbed by the cement.

We took cement samples from the mill outlet to check particle size. The fineness values by the 45 μm sieve method were 7.1%, 5.5%, and 6.0%. These values basically matched the results from laser particle size analysis: 6.79%, 5.22%, and 5.25%. The specific surface area values by the Blaine air permeability method were 342 m²/kg, 336 m²/kg, and 345 m²/kg. The particle size distribution uniformity coefficients were 1.107, 1.042, and 1.090. In a closed-circuit grinding system, this indicates a relatively narrow particle size distribution. The content of <3 μm particles was 18.68%, 19.04%, and 19.15% respectively, indicating a relatively high fine powder content. This high fine content likely induced the cement balling and clumping.

Reviewing public meteorological data for Plant A’s region in recent years showed a general upward trend in average air relative humidity. Furthermore, the relative humidity exceeded 80% in the past year. This humid air promoted moisture absorption and hydration of the cement during storage.

Therefore, we concluded that the primary cause of clumping at Plant A was the high content of fine powder (<3 μm). High temperatures caused dehydration of the desulfurized gypsum. This effect, combined with moisture from the air, jointly induced cement hydration and hardening. This process started with nucleation and ball formation, gradually growing into lumpy formations.

3. Improvement Measures and Results

Based on the above conclusions, Plant A implemented the following measures:

(1) Reduced the temperature of cement leaving the mill by increasing airflow at the mill tail and introducing more cooling air at the classifier. They also regularly switched the clinker discharge outlet. Consequently, the mill outlet gas temperature decreased from 100°C to around 90°C.

(2) Reduced the proportion of desulfurized gypsum from 5.5% to 4.8%.

(3) Enhanced the dispersing effect of the grinding aid to speed up material flow in the ball mill. This increased the ball mill’s circulation load, reduced localized heat buildup, and minimized the generation of fine powder. The content of <3 μm fine powder was controlled below 17%. Additionally, they minimized the cement storage time in the silos.

After consuming the existing stock of stored cement over a period, the amount of balled and lumpy cement extracted from the silos significantly decreased. For the past six months, no further incidents of discharge outlet blockage or material buildup during train loading have occurred.

4. Conclusion

The main causes of cement clumping at Plant A were the high temperature of the incoming cement, which converted the crystalline water in desulfurized gypsum into free water, and the subsequent slow absorption of moisture from the humid environment during storage. This increased the cement’s moisture content. The high proportion of fine powder (<3 μm) in the cement led to pre-hydration of some fines, gradually forming large clumps. The implemented measures successfully resolved the clumping issue.