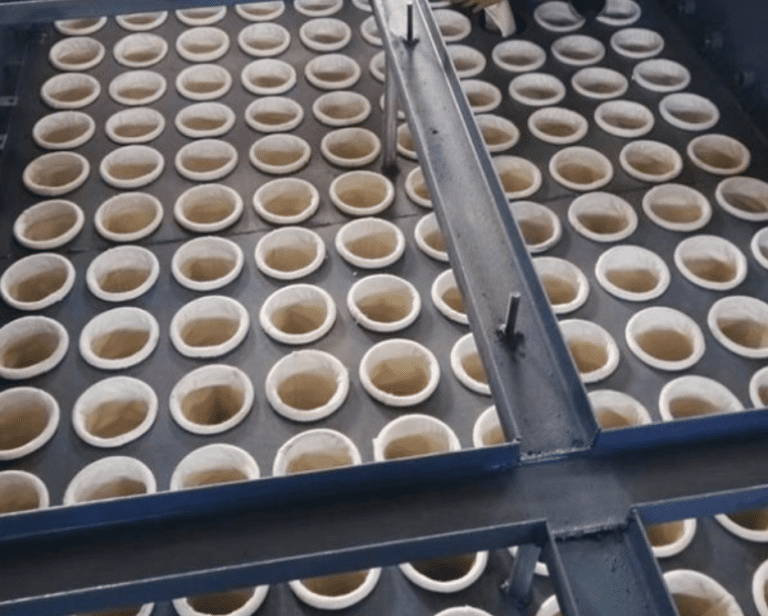

В этой статье рассматривается превосходная эффективность удаления пыли с помощью Рукавные фильтры на электростанциях по сжиганию мусора, эффективность удаления пыли составляет более 99,8%, и даже до 99,99%. Однако в процессе эксплуатации и управления все еще существует множество проблем. Поэтому в данной статье анализируются общие проблемы эксплуатации рукавных фильтров на мусоросжигательных электростанциях и предлагаются соответствующие решения.

I. Часто задаваемые вопросы

1.Чрезмерное сопротивление движению

Нормальным явлением является увеличение сопротивления рукавного фильтра в процессе работы. Если сопротивление находится в умеренно высоком состоянии, операторы часто не обращают внимания на эту проблему. Однако в действительности увеличение сопротивления приводит к росту потребления энергии и представляет угрозу для срока службы рукавного фильтра. Длительная работа в таком состоянии не только сокращает срок службы фильтрующего мешка, но и представляет угрозу для оборудования и системы подачи воздуха

Если сопротивление сильно превышает норму, это может привести к повреждению фильтровального мешка, в результате чего система пылеудаления не сможет работать должным образом, что приведет к увеличению эксплуатационных расходов и снижению экономической выгоды. К числу распространенных причин высокого рабочего сопротивления относятся:

- Расчетная скорость ветра фильтрации слишком высока

- Неправильный выбор фильтрующего материала

- Решение проблемы недостаточного объема воздуха

- Увеличение производства после технологического преобразования

Хотя рукавные фильтры обладают высокой эффективностью удаления пыли, их широкомасштабное применение на электростанциях для сжигания отходов ограничено из-за их высокой эксплуатационной стойкости и больших затрат на обслуживание.

2.Короткий срок службы фильтровального мешка

Срок службы фильтровальных мешков зачастую невелик и требует частой замены, что негативно сказывается на экономических преимуществах производства электроэнергии путем сжигания отходов. Срок службы некоторых фильтровальных мешков достигает 30000 часов, в то время как другие можно использовать только в течение 8000 часов или даже короче. К факторам, сокращающим срок службы фильтровальных мешков, относятся:

- Качество фильтрующего материала не соответствует требованиям условий работы

- Скорость ветра при фильтрации слишком высока

3.Трудности с удалением пыли с пылесборника

Скопление пыли на поверхности фильтровальных мешков - распространенная проблема на электростанциях по сжиганию отходов. Возникновение этой проблемы связано с неправильным контролем за дымовой газ температура и особый состав дымовых газов после сжигания.

4.Неисправность оборудования для транспортировки золы

Система сбора пыли в мешках включает в себя ковшовые элеваторы и шнековые конвейеры, в обоих случаях часто происходит засорение золой.

II. Анализ причин

Низкий коэффициент использования площади фильтрации

Количество летучей золы, переносимой дымовыми газами, проходящими через рукавный фильтр, относительно невелико, и большая часть летучей золы оседает в нижней части рукава, что приводит к недостаточному использованию фактической площади фильтрации и сильному износу рукава.

Недостаточный контроль автоматизации

Автоматизированные системы управления часто не являются достаточно полными. Чувствительность температурного датчика низкая, что приводит к отклонению между отображаемой температурой и фактической температурой дымовых газов, заставляя операторов делать неверные выводы.

III. Решения

A. Оптимизируйте метод очистки от пыли

Обычно используются такие методы очистки рукавных фильтров, как очистка обратным дутьем, вибрационная очистка и импульсная очистка. Рекомендуется использовать разделенную конструкцию, чтобы облегчить обслуживание и не нарушить работу мусоросжигательной печи.

B.Разумный выбор фильтрующего материала

Фильтрующие материалы следует выбирать в зависимости от характеристик дымовых газов, принимая во внимание такие факторы, как температура, влажность, коррозионная активность и концентрация пыли.

C. Контролируйте кислотную точку росы дымовых газов

Когда температура дымовых газов ниже определенного значения, кислотные вещества могут разъедать оборудование и образовывать липкий слой пыли на поверхности фильтрующего материала. Для решения этой проблемы можно принять такие защитные меры, как подогрев бункера для золы.

D. Обслуживайте систему транспортировки золы

Для такого оборудования, как Шнековые конвейеры и ковшовые элеваторыПоэтому необходимо регулярно проверять содержание влаги в золе. Правильное увеличение скорости конвейера также может помочь уменьшить проблему засорения золы.

Улучшите систему управления автоматикой

Комбинируя удаленный мониторинг с ручной проверкой, можно добиться всестороннего контроля и повысить уровень автоматизации управления.

Заключение

Проанализировав проблемы и решения, связанные с применением рукавных фильтров на электростанциях по сжиганию отходов, можно убедиться, что правильный выбор и оптимизация системы пылеудаления имеют огромное значение для повышения экономической выгоды и защиты окружающей среды. Если у Вас возникли вопросы или потребности, связанные с рукавными фильтрами и сопутствующими технологиями, пожалуйста, не стесняйтесь связаться с нами в любое время. Мы будем стремиться предоставить Вам высококачественное обслуживание.