Powder silos are critical industrial storage solutions used for material homogenization, bulk storage, and production balancing across industries like cement, food processing, chemicals, and pharmaceuticals. However, many companies face challenges such as low storage capacity, poor material flow, clogging issues, and inefficient discharge systems, leading to production delays and increased costs.

In this guide, we explore powder silo optimization techniques, including discharge cone redesign, air homogenization improvements, and advanced conveying systems, to enhance silo performance, material flow efficiency, and operational reliability.

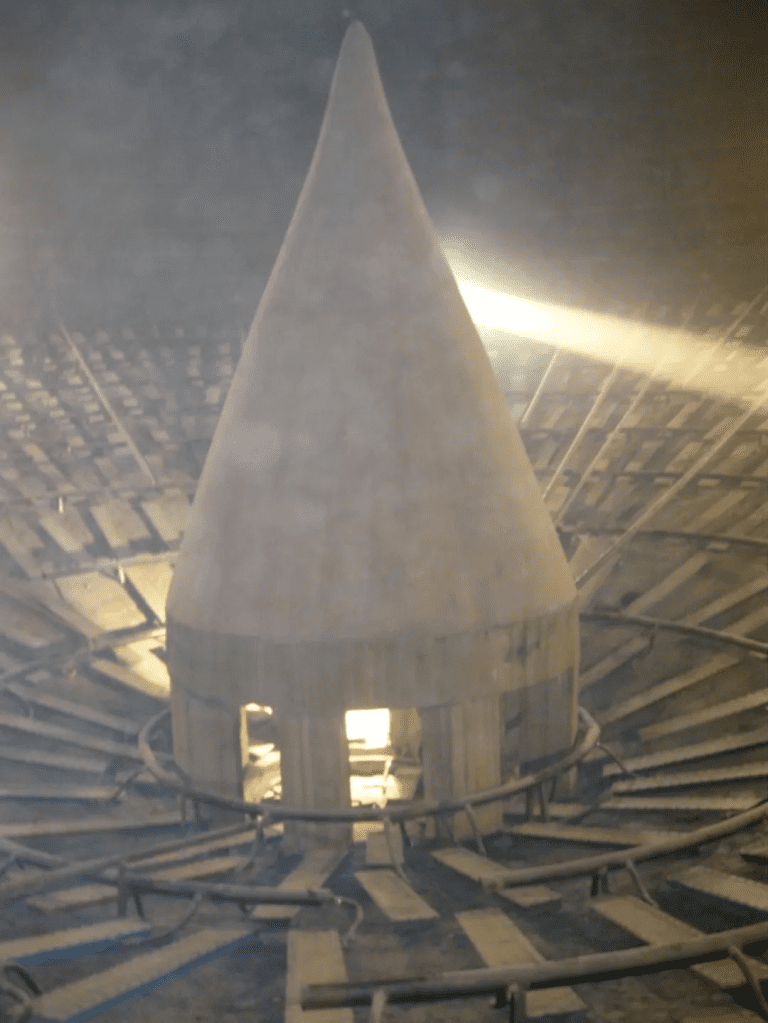

1. Discharge Cone Optimization for Better Material Flow

A common feature in powder storage silos is the discharge cone, designed to reduce material pressure and facilitate smooth flow. However, many silos still experience clogging, erratic discharge, and poor flow control, especially when aeration systems are inactive.

Key Improvement: Replace Discharge Cones with Smart Flow Valves

Problem: Traditional discharge cones often fail to prevent material bridging and uneven flow.

Solution: Install a high-efficiency flow control valve at the silo outlet.

Real-time pressure monitoring ensures optimal material flow.

Automated opening/closing (similar to ABS brakes in vehicles) prevents overpressurization and material blockages.

Reduces maintenance costs and improves silo discharge reliability.

2. Air Homogenization: Myths vs. Reality

Many manufacturers believe air homogenization systems actively mix materials, but their primary role is to ensure consistent discharge, not forced blending.

How Silo Homogenization Really Works

Natural homogenization occurs as materials enter and exit the silo.

Aeration systems primarily prevent material compaction and rat-holing.

Overuse of air mixing can weaken silo structural integrity and increase energy waste.

Maintenance Tips for Long-Term Efficiency

Regularly inspect fluidization pads and aeration nozzles.

Clean silo interiors to prevent material buildup and cross-contamination.

Optimize air pressure settings to balance discharge speed and energy consumption.

3. Choosing the Best Discharge Equipment for Powder Silos

The right silo discharge system ensures smooth material flow, accurate metering, and reduced downtime. Common options include:

A. Air Slide Conveyors (Low-Cost but Limited)

Pros: Affordable, energy-efficient, and dust-tight.

Cons: Struggles with wet materials, clumps, and abrasive powders.

B. Air Chain Conveyors (Superior Alternative)

Combines chain conveyors + air slide technology for high-efficiency powder handling.

Handles moist/clumped materials better than traditional systems.

Lowers silo foundation height, reducing construction costs.

According to leading silo engineering firms, switching to air chain conveyors can:

✔ Cut operational costs by up to 30%

✔ Improve material flow reliability

✔ Reduce maintenance frequency

Conclusion: Optimize Your Powder Silo for Peak Performance

Upgrading powder storage silos with smart flow valves, optimized aeration, and advanced conveyors can boost efficiency, minimize downtime, and extend equipment lifespan.

If you have any questions about silo design or related equipment, feel free to contact us. We are Darko, and we are here to provide you with professional support and solutions!