What is an Air Slide?

Air slide conveyors are a highly efficient solution for pneumatic conveying of powdered materials, offering low energy consumption, minimal maintenance, and smooth material flow. These conveyors are widely used in industries such as cement, fly ash handling, mineral processing, and food production, where gentle and consistent material transfer is critical.

At Darko, we specialize in custom air slide conveyor systems, including reversible designs for bidirectional material flow. In this article, we explore the key advantages, working principles, and technical innovations that make air slide conveyors an optimal choice for bulk material handling.

How Air Slide Conveyors Work?

Air slide conveyors operate on the principle of aeration and gravity flow:

Fluidization – Compressed air permeates through a porous media (typically a fabric or ceramic plate), turning powdered material into a fluid-like state.

Gravity-Driven Flow – The material moves along a slight incline (typically 3-6°) due to gravity, requiring no mechanical moving parts.

Controlled Discharge – Adjustable air pressure ensures precise material flow regulation, preventing clogging or uneven distribution.

Key Benefits of Air Slide Conveyors

✔ Energy Efficiency – Low power consumption compared to screw or belt conveyors.

✔ Minimal Wear & Maintenance – No chains, belts, or rotating parts to replace.

✔ Gentle Material Handling – Ideal for fragile powders (e.g., cement, fly ash, alumina).

✔ Dust-Free Operation – Enclosed design reduces contamination risks.

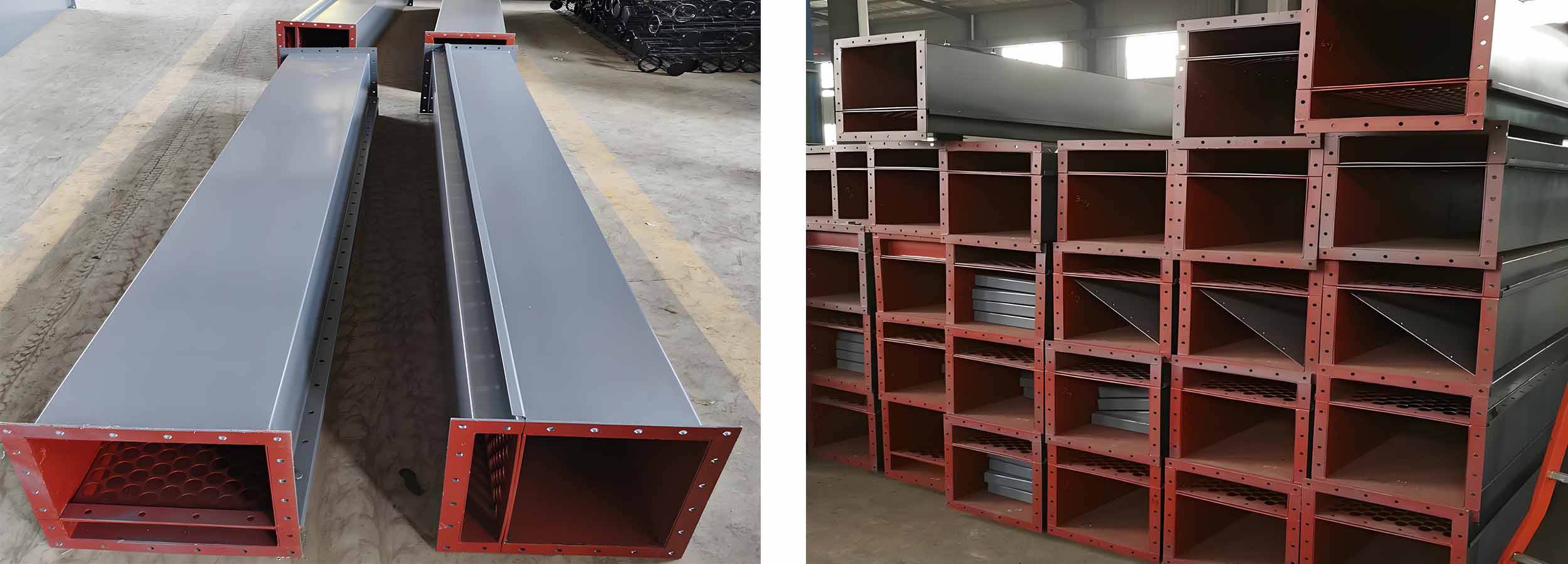

Darko’s Innovations in Air Slide Conveyor Design

1. Reversible Air Slide Conveyors for Flexible Material Flow

Unlike traditional unidirectional models, reversible air slide conveyors allow bidirectional material transfer, making them ideal for:

Loading/unloading storage silos

Blending different materials without multiple conveyors

Space-constrained facilities requiring compact logistics

Case Study: 70m Long Reversible Air Slide Conveyor

In 2022, Darko engineered a 300t/h reversible air slide conveyor for mineral powder storage, featuring:

Single-end drive system (reducing mechanical complexity)

Hybrid chain tensioning (weight + screw mechanism for 70m+ spans)

High-pressure air-assisted discharge (preventing blockages)

2. High-Capacity & Long-Distance Adaptatio

Standard air slide conveyors are limited to short distances (typically <30m). Darko’s enhancements enable:

✅ Extended lengths (up to 100m) with optimized aeration zones

✅ Higher throughput (500t/h+) via multi-chamber airflow control

✅ Intermediate discharge points without flow disruption

3. Advanced Aeration Systems for Challenging Materials

Variable air pressure zones prevent material segregation (e.g., coarse vs. fine particles).

Ceramic aeration plates (instead of fabric) for abrasive materials like silica sand.

Choosing the Right Air Slide Conveyor

| Factor | Consideration |

|---|---|

| Material Type | Powder fineness, abrasiveness, moisture |

| Capacity Needs | Throughput (t/h) and conveyor length |

| Layout Constraints | Incline angle, horizontal/vertical routing |

| Reversible Requirement | Bidirectional flow vs. fixed-direction |

Pro Tip: For sticky or hygroscopic powders, a heated air slide conveyor prevents material buildup.

Conclusion

Darko’s air slide conveyors combine proven pneumatic principles with cutting-edge innovations, delivering:

Lower operational costs (energy + maintenance savings)

Custom configurations (reversible, long-distance, high-capacity)

Reliable performance in cement, mining, and chemical industries

Ready to optimize your material handling? Contact Darko for a free consultation on air slide conveyor solutions.