لقد تطورت تقنية إزالة الغبار للغلايات التي تعمل بالفحم من إزالة الغبار الغشائي المائي وإزالة الغبار الكيسي إلى إزالة الغبار الكهروستاتيكي. ومع تزايد المعايير البيئية الصارمة على نحو متزايد والترويج لمرشحات الأكياس وتطبيقها، فإن القيود المفروضة على المرسبات الكهروستاتيكية تتضح تدريجياً.

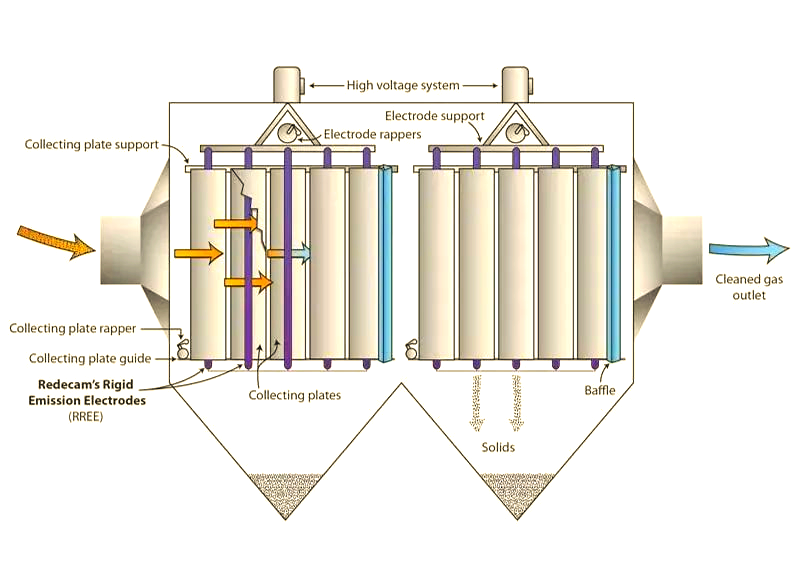

لم يعد المرسب الكهروستاتيكي (ESP)، الذي كان معيارًا في الصناعة، قادرًا على تلبية المتطلبات الحالية بسبب ارتفاع تكاليف الصيانة وضعف القدرة على التكيف مع أنواع الفحم وانخفاض الكفاءة. أصبح المرشح الكيسي النفاث النبضي النفاث، الذي يتميز بكفاءة إزالة الغبار التي تزيد عن 99%، وانخفاض تكاليف التشغيل على المدى الطويل، ومزايا الامتثال للأتمتة، خيارًا أفضل.

لماذا تصبح المرسبات الكهروستاتيكية قديمة تدريجيًا؟

1. مشكلة تدهور الكفاءة

ستنخفض كفاءة إزالة الغبار الأولية 99% للأسباب التالية:

- تغيير نوع الفحم (غبار المقاومة النوعية العالية يقلل من أداء ESP)

- يتسبب تآكل القطب الكهربائي وتراكم الغبار في تشويه المجال الكهربائي

- وغالبًا ما تتجاوز الانبعاثات الفعلية 100 ملجم/م³، وتواجه خطر الغرامات

2. تحدي "النمر الكهربائي": ارتفاع تكاليف التشغيل

- يبلغ استهلاك الطاقة 3-5 أضعاف استهلاك مرشح الكيس (ومن هنا جاء لقب "النمر الكهربائي")

- تؤدي الصيانة المتكررة مثل استبدال القطب الكهربائي إلى زيادة تكاليف العمالة

3. القيود الهيكلية والمتطلبات المكانية

يتطلب مساحة كبيرة من الأرض وهيكل إطار من الصلب الثقيل

تتطلب أنظمة الجهد العالي المعقدة صيانة من قبل فنيين محترفين

المزايا التقنية للمرشح الكيسي

1. أداء ممتاز في إزالة الغبار

- الحفاظ على كفاءة مستقرة أعلى من 99.5%، لا تتأثر بالمقاومة النوعية للغبار

- يفي بالمعايير GB13223 ومعايير بكين للانبعاثات المنخفضة للغاية ومعايير توجيهات الاتحاد الأوروبي للانبعاثات الصناعية (IED)

2. انخفاض التكاليف مدى الحياة

| عامل التكلفة | أجهزة ESPs | بيوت الأكياس |

|---|---|---|

| الاستثمار المبدئي | عالية (4 مجالات ESPs عالية التكلفة ~20120% أكثر) | تنافسية (متناقصة بسبب إنتاج المرشح الموضعي) |

| استهلاك الطاقة | 500-800 كيلوواط | 100-200 كيلوواط |

| الصيانة | الإصلاحات المتكررة للقطب الكهربائي | التنظيف الآلي بالنبض النفاث النبضي (أقل وقت تعطل) |

3. تطيل وسائط الترشيح المتقدمة من عمر الخدمة

عصري PTFE-مطلي, ص84 أليافو أغشية الألياف النانوية قاوم:

درجات حرارة عالية (تصل إلى 260 درجة مئوية)

رطبة وحمضية غاز المداخن

يبلغ العمر الافتراضي لكيس الفلتر من 5 إلى 7 سنوات، وهو أفضل بكثير من دورة الاستبدال التي تتراوح بين 2-3 سنوات لأقطاب ESP

الأسئلة الشائعة: مجمعات الغبار الكيسية

س: هل يمكنه التعامل مع غاز المداخن عالي الحرارة؟

أ : يمكن أن تتحمل ألياف السيراميك ووسائط الترشيح الشبكية المعدنية درجات الحرارة العالية التي تزيد عن 300 درجة مئوية

س : ما هو تكرار استبدال كيس الفلتر؟

A: 3-5 سنوات مع إجراء الصيانة المناسبة (مقابل الإصلاحات نصف السنوية لأجهزة ESPs).

س: هل الغلاية الصغيرة مناسبة؟

أ : تصميم معياري يمكن أن يتكيف مع الغلايات بمقاييس مختلفة

إذا كنت بحاجة إلى معرفة المزيد عن حلول تكنولوجيا إزالة الغبار للغلايات التي تعمل بالفحم، فلا تتردد في اتصل بنا في أي وقت، وسنقدم لك المشورة المهنية.