What’s a Bag Filter, and Why Should You Care?

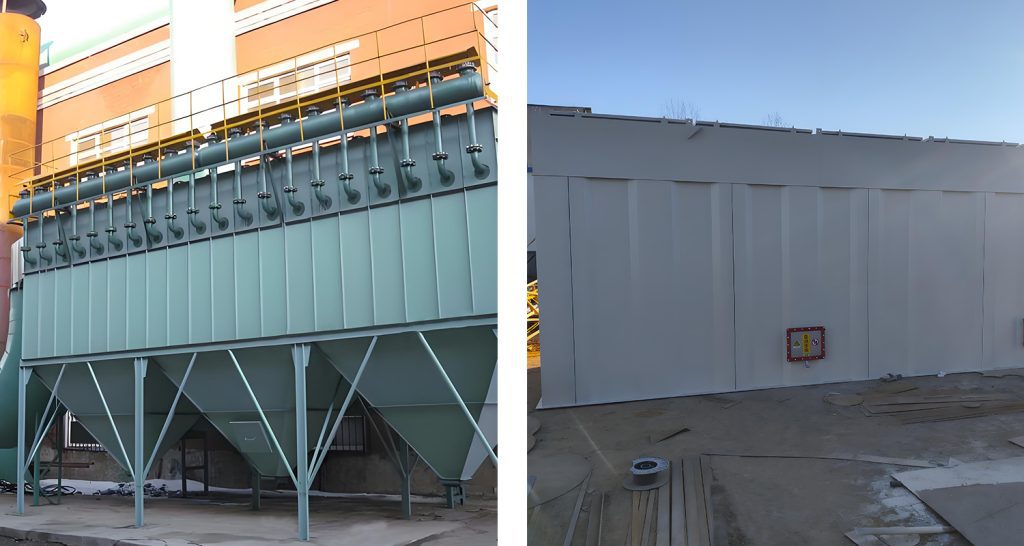

If you’ve ever seen the inside of a cement plant, you know it’s not the cleanest place on earth. Dust is everywhere. It clings to machinery, gets into people’s lungs, and settles over everything. That’s where the bag filter comes in. It might not look like much at first glance, just a bunch of long fabric bags inside a metal housing, but this one piece of equipment can make a huge difference.

Bag filters are dust collectors. They grab the fine particles floating in the air, especially during processes like material handling, silo discharge, or bulk loading and trap them before they get out into the plant (or worse, the environment). So if you’re dealing with cement, lime, fly ash, or any other dusty material, the bag filter isn’t optional. It’s necessary.

What makes this piece of equipment essential is not just the dust it traps, but the consistency with which it does so. Whether your plant runs in hot climates, deals with high volumes, or operates in tight spaces, bag filters work without drawing attention to themselves. They keep things running, help maintain compliance with air quality standards, and protect your crew from long-term exposure risks, without halting production.

The Problem with Dust, and How Bag Filters Fix It

Let’s keep this real. Dust is more than just a nuisance. For people working on-site, it’s a serious health risk. Inhaling fine particles day after day can cause long-term respiratory problems. Plus, it creates safety hazards, machines clog, visibility drops, and slippery surfaces cause accidents.

On the operational side, dust also kills efficiency. Imagine fine cement powder getting into moving parts of your equipment. It wears things down faster, leads to more breakdowns, and adds maintenance costs. Over time, that hits your bottom line.

This is exactly why more and more cement companies are investing in better dust control systems. Bag filters, especially pulse jet bag filters, offer a simple solution. They catch dust before it becomes a problem.

Why Pulse Jet Bag Filters Are the Go-To Choice

There are different types of bag filters, but pulse jet is the one that stands out in modern cement equipment setups. Here’s why:

- They clean themselves: A jet of compressed air knocks the dust off the bags regularly, which means they don’t get clogged easily. That self-cleaning feature keeps things running without manual interruption, and in a place where dust builds up fast, that’s a big deal.

- They are so compact:Pulse jet filters are useful in busy facilities where saving space is crucial. When your plant is packed with production areas, a filter that doesn’t take up too much space is very useful.

- A smoother and cleaner exhaust system:Means the bags last longer. So, assets last longer, there are fewer shutdowns and it costs less over the years. Equipment that stands the test of time helps you save money as well as reduce waste.

- They’re simple to manage: You can easily repair small problems or replace bags without turning off the whole server. Maintenance crews can handle small fixes quickly, and production doesn’t have to stop while the dust collector gets a tune-up.

What really makes pulse jet filters the go-to isn’t just their performance, it’s the way they fit into a working environment. They’re designed with the operator in mind. If your plant needs to keep moving, handle tough dust, and avoid unnecessary breakdowns, this system quietly does its part. It’s a win-win situation: your air stays clean, and your operations run smoothly, without the headaches that come with older or bulkier setups.

Where You’ll Find Bag Filters Doing the Hard Work

Bag filters aren’t just for cement plants, although that’s where they shine the most. Here’s a breakdown of where they’re used and why they matter:

- Cement Plants: From raw material intake to final packing, dust control is needed at every stage. Bag filterscatch particles before they spread.

- Power Plants: When coal or biomass burns, fine ash particles rise. Bag filtersstop them from polluting the air.

- Chemical Plants: Many chemical processes produce airborne particles. Bag filtershelp keep emissions within safe limits.

- Pharmaceutical Plants: Even in high-precision settings, bag filtershelp manage air purity.

- Waste-to-Energy Plants: Ash and residue particles are common. Bag filterskeep them contained.

- Foundries, Ports, Mining, Food Processing, Aerospace: Any industry dealing with powders or bulk materials benefits from using them.

If dust is part of your daily challenge, the bag filter should be part of your daily solution.

Darko’s Bag Filters: Simple, Smart, and Built for You

At Nantong Darko Building Materials Machinery Co., Ltd., we don’t just sell equipment, we solve problems. That means understanding your specific site, your material flow, and your challenges. Our bag filter systems are custom-built. Whether you’re handling fly ash at a power plant or cement dust from a bulk loader, we design around your workflow.

We’re not interested in offering a generic fix. Our team works with you one-on-one. That’s part of what sets us apart, personalized service that feels more like a partnership than a sales pitch.

When we build or install a bag filter system, we make sure it fits your plant, your people, and your goals. No over-engineering. No unnecessary tech. Just clean air, better safety, and long-term savings.

What Makes Us Different from the Rest?

You’ve probably come across a dozen suppliers selling bag filters. So what makes us different? Here’s the honest answer:

- We listen. Every site is different. Every client has different priorities. We don’t assume, we ask.

- We stick with you. From planning to post-installation support, we stay in the loop.

- We keep it simple. Our solutions are practical, not flashy.

- We move fast. You’ve got timelines, and we respect them.

And above all, we stay focused on delivering energy-saving, low-emission, and cost-effective systems. That’s how we help you stay ahead.

Not Just a Filter, A Full Dust Control Solution

Let’s be clear, installing a bag filter is just the start. At Darko, we look at the full picture. That means integrating the filter with:

- Bulk loader systems: So dust doesn’t escape during truck or railcar loading.

- Conveying systems: So material movement doesn’t stir up clouds of fine particles.

- Silos and discharging systems: So fine powder doesn’t pollute your worksite during storage or release.

We also support parts like expansion joints, slide gate valves, rotary valves, and butterfly valves to keep everything moving safely and efficiently.

Dust control isn’t a side job. It’s part of your plant’s core health. And we treat it that way.

Real Results That Matter

Let’s say you’re running a mid-size cement facility. Without a solid dust collection system, you’re dealing with frequent shutdowns, staff complaints, failed inspections, and cleanup costs.

After installing a Darko bag filter system, the change is obvious:

- Dust levels drop by over 90%

- Maintenance staff spends less time cleaning up

- Employees work in safer, cleaner conditions

- Regulatory compliance becomes easier

- You use less energy and save on fines or downtime

This isn’t a theory. This is the day-to-day reality of clients we’ve worked with. And we’re ready to help you see the same results.

How to Get Started with the Right Bag Filter

Not sure what kind of filter you need? No problem. That’s what we’re here for.

When you reach out to us, we’ll take a look at:

- Your current dust challenges

- Your plant layout

- Your material type and volume

- Your airflow and pressure requirements

From there, we recommend the right solution, whether it’s a small single-point dust collector or a plant-wide bag filter setup with integrated ducting and valves.

No pressure. No upselling. Just straight advice based on what works.

Final Thoughts: Cleaner Plants, Healthier Teams, Better Business

You don’t need to wait until regulators come knocking or workers start complaining. Investing in a bag filter system today can prevent a lot of problems tomorrow.

If you’re serious about making your cement plant cleaner, safer, and more efficient, then this is where you start. A bag filter might seem like a simple piece of gear, but in the long run, it’s a smart investment.

Talk to Us

We’re always ready to help. If you’re updating or building your old system or starting fresh, feel free to get in touch with us. Tell us what you require and we’ll see how we can deliver it.

Call Darko Today. Let’s Keep Your Plant Clean.