The star discharge valve, also known as the rotary discharge valve, is widely used in industries such as chemicals, coal, metallurgy, and food processing. It’s usually placed at the start or end of other equipment, like the point where bag filters release air or where pneumatic communicating systems begin.This valve mainly helps powdered materials move downward naturally, using gravity. It also isolates the gas systems above and below, preventing interference.

Structure and Principle of the Star Discharge Valve

The star discharge valve is a key device in the transportation of powdered or fine particulate materials. It acts as a transitional device that effectively isolates the gas phases of two systems. Typically, the star discharge valve is installed vertically, with the valve shaft positioned horizontally, allowing gravity to continuously transport materials from the top to the bottom.

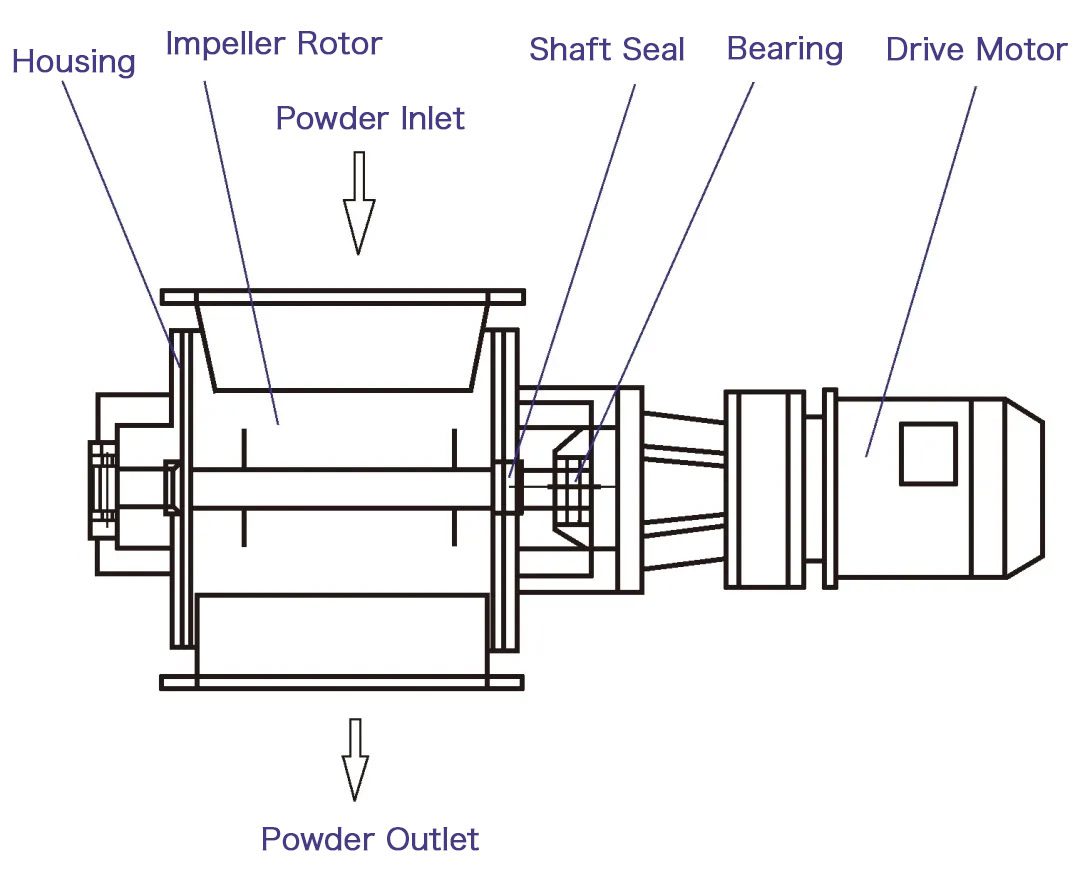

This valve consists of a housing, an impeller rotor, shaft seals, bearings, and a drive motor. During operation, fine powders or particles fall into the impeller slots under gravity. The impeller spins and pushes the materials down into the collection hopper or into the pneumatic expressing system.Throughout this process, the impeller maintains gas isolation between the upper and lower sections by fitting closely with the inner wall of the housing.

Analysis of Axial Leakage Causes

Common faults during the operation of the star discharge valve include seal failure, bearing wear, and impeller jamming. Among these, axial leakage is the root cause of these issues. Seal failure typically arises from axial leakage of materials, which in turn leads to bearing wear and impeller jamming.

Causes of Seal Failure

A newly installed star discharge valve usually does not show axial leakage in the early stages of use. However, as usage time increases, leakage gradually worsens. When inspecting the sealing surface of the impeller shaft, noticeable wear marks can be observed. The numbers show that how tough and strong the powder particles are can really influence how long the valve lasts. High-hardness catalytic cracking catalyst powders can easily wear down the sealing surfaces during continuous friction, leading to leakage.

Structural Improvement Solutions

To address the leakage issue of the star discharge valve, the following effective improvement measures can be implemented:

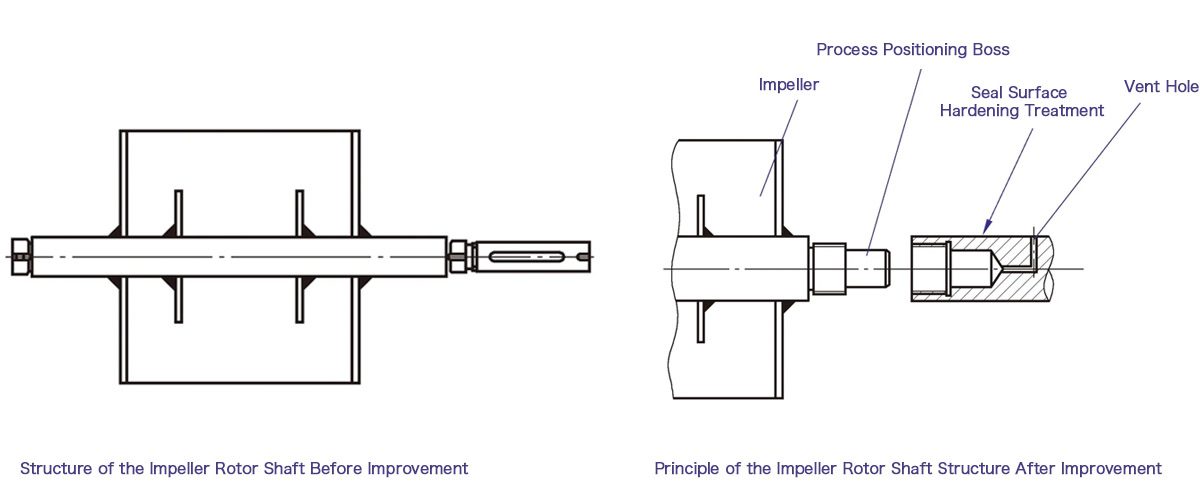

1. Improve the Wear Resistance of the Impeller Rotor Shaft

Enhancing the wear resistance of the impeller rotor shaft surface is essential for extending the equipment’s lifespan. Increasing the surface hardness of the shaft, ensuring it exceeds the hardness of the powder material, can effectively reduce wear. This can be achieved by:

- Using high-strength alloy steel materials, such as 2Cr13 or 3Cr13, and applying heat treatment.

- Implementing surface treatments like chrome plating, hard alloy spraying, or laser cladding.

2. Improve the Structure of the Impeller Rotor Shaft

Designing the impeller rotor shaft as a split structure can reduce maintenance costs and time. Using threaded connections allows for quick replacement of the shaft heads when seals fail, minimizing the risk of replacing the entire unit. Making sure the thread goes in the right direction so it matches the motor’s spin can help stop jams and avoid breakdowns.

The star discharge valve has been running smoothly for more than a year now, with no leaks along the axis, which means it’s lasted much longer than before.

Industry Applications

| Industry | Use Case | Recommended Valve Type |

|---|---|---|

| Cement | Kiln feed systems | High-temp PPS seals |

| Food | Flour conveying | FDA-grade stainless |

| Pharma | Powder transfer | CIP-compatible design |

Conclusion

Through in-depth analysis of the faults in the star discharge valve, we identified the root causes of axial material leakage and developed effective improvement measures. These not only extend the equipment’s lifespan but also reduce maintenance costs. The key measures are:

1.Increase the hardness of the sealing surfaces to enhance wear resistance, significantly extending the equipment’s lifespan.

2.Use a split structure for the sealing shafts to lower maintenance costs and reduce repair time.

With these improvements, the performance of the star discharge valve has significantly enhanced, providing more reliable solutions for material transport in relevant industries. For more information about our products or services, please contact us. We look forward to providing you with quality solutions!