The cement grinding process uses an open-circuit combined system. This system consists of a Φ200-180 roller press and a Ø4.2m×13m ボールミル. However, the system’s recirculating material elevator faced major issues. It operated under high load and current. Consequently, the chains, buckets, and the dispersion grating in the V-type separator experienced severe wear. This led to a high failure rate, significant maintenance workload, and costly repairs. Ultimately, these problems resulted in low system output and high power consumption for cement grinding.

A new elevator was added to the roller press system. This modification not only reduced the load on the original recirculating elevator but also increased the roller press circulation rate. Furthermore, it lowered the failure rate, maintenance effort, and costs. The goal of increasing production and reducing consumption was successfully achieved.

はじめに

A company operates one 5000t/d clinker line and one 2500t/d clinker line. The 5000t/d line began operation in November 2020. Its supporting #3 cement grinding line uses the open-circuit combined grinding process with a Φ200-180 roller press and a Ø4.2×13m ball mill. The line has a designed mill output of 260 t/h and an annual capacity of 1.9 million tons.

Currently, the #3 cement grinding system is limited by the insufficient capacity of the existing recirculating material elevator from the roller press. This causes low cement output and high power consumption. Therefore, the company decided to retrofit the roller press system by adding a new elevator.

Pre-Retrofit Situation

The #3 cement grinding system uses the open-circuit combined grinding process with a Φ200-180 roller press and a Ø4.2m×13m ball mill. Currently, for producing P·O 42.5 cement, its output is 240-270 t/h, and its grinding power consumption is 33-34 kWh/t. Compared to other systems with the same main equipment, its capacity is relatively low and its power consumption is high.

The original recirculating elevator had a designed capacity of 1650 t/h and a maximum capacity of 2000 t/h. The roller press’s designed throughput is 1500-1800 t/h. Additionally, 260-280 t/h of fresh feed also first enters this recirculating elevator. It mixes with the recirculating material and together enters the V-type separator (hereafter “V-Separator”). Thus, the required handling capacity for the recirculating elevator reaches 1760-2060 t/h.

To ensure stable and safe operation, the load rate of the recirculating elevator could only be controlled at 85%-90%, meaning an actual handling rate of 1700-1800 t/h. Otherwise, the elevator motor current would frequently alarm, exceeding 390 A. It could not meet the system’s maximum circulation rate requirement for efficient production (around 2200 t/h).

Due to the high material throughput, heavy load, and high current, the chains, buckets, and the V-Separator’s dispersion grating wore severely. This led to a high failure rate in the recirculating elevator’s reducer, requiring substantial maintenance work and cost. A full set of elevator chains and buckets needed replacement every 1.5 years, costing over 1 million RMB. The reducer failed multiple times within a year.

Consequently, production could only continue by reducing the volume of recirculating material in the roller press system. This limited the system output and resulted in high power consumption per ton of cement.

Retrofit Solution

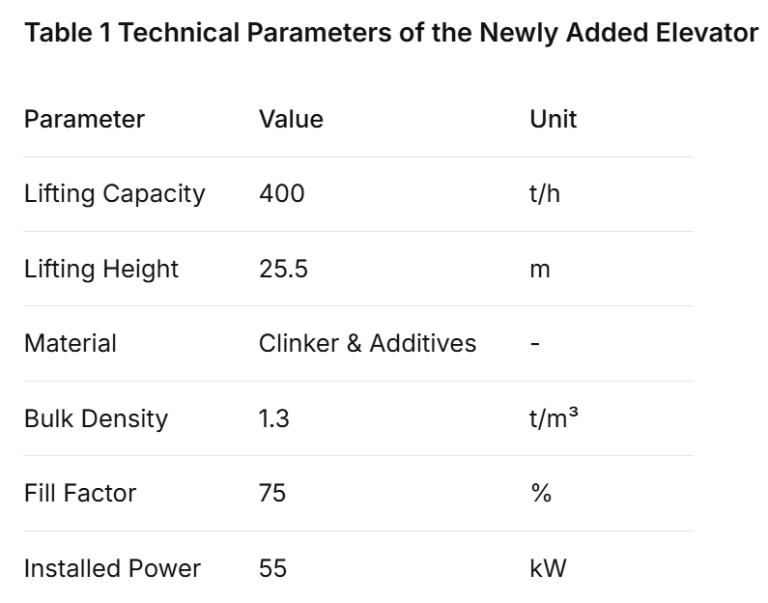

After comparing several technical modification plans, the company decided to add a new elevator to the roller press system (see Table 1).

The head and drive system of the existing belt conveyor from the cement blending silo were moved 2 meters towards the silo to make space for the new elevator. The existing external discharge bin was dismantled, and the new elevator was installed on the ground level at 0.000m. Openings were created in the existing floor slabs at elevations 6.000m, 12.500m, 23.000m, 30.000m, and 37.500m for the new elevator to pass through.

The existing dust collector was utilized. The small dust collector and fan located on the 12.500m level were relocated to provide dust control for the new elevator’s transfer points. A maintenance steel platform was installed at the head of the new elevator, and some existing steel structures were reinforced.

Power and control cables for the new elevator were connected to spare circuits in the existing power distribution room, and new local start/stop buttons were installed. The new elevator transports fresh feed to the feed pipe at the top of the stabilizing bin, where it mixes with the material exiting the V-Separator before entering the bin.

Modifications were also made to the roller press stabilizing bin section: The diameter of the existing chute from the V-Separator to the stabilizing bin was increased to prevent clogging. Fresh feed now enters this chute vertically to prevent material segregation; the chute was lined with wear-resistant plates. A distribution plate was installed inside the stabilizing bin to prevent segregation, and the bin’s cone section was modified and lined with wear-resistant plates.

The chute from the stabilizing bin to the roller press was replaced. A manual rod gate was installed for maintenance purposes, and the size of the pneumatic flap valve was increased to ensure stable material level and pressure before the roller press. The original roller press feeding device and internal baffle plates were replaced to allow for adjustment ensuring uniform roll gap.

Civil engineering work for the new elevator’s foundation, along with equipment installation and no-load trial runs, was completed during production periods. Final integration into the system required only a mill shutdown for maintenance to connect the interfaces.

The new elevator has a capacity of 400 t/h (max 450 t/h), meeting production needs. It is equipped with a speed sensor and level indicator at the bottom to monitor operation. The original system where fresh feed entered the recirculating elevator was retained as a backup in case of failure of the new elevator, preventing production stoppages.

Problem Resolution During Trial Operation and Retrofit Results

During initial trial operation, the new elevator frequently experienced low-speed, high-level, and overload alarms, causing trips. Analysis showed these were false alarms triggered by material buildup creating a high level in the elevator boot. The inlet opening width and its distance to the buckets were reduced, and the elevator’s tensioning device was readjusted. After these measures, the new elevator operation gradually normalized.

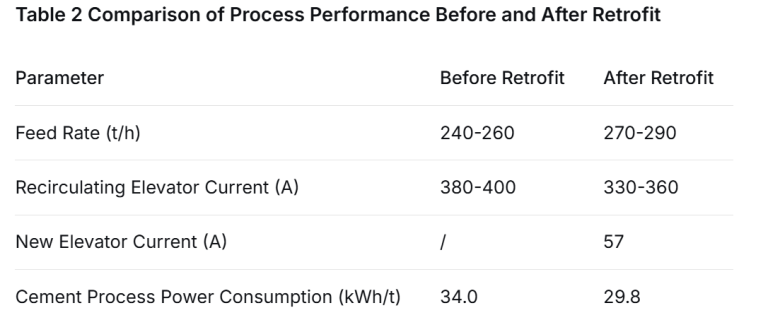

Key process parameters for producing P·O 42.5 cement before and after the retrofit are shown in Table 2.

結論

The cement combined grinding system returned to normal production shortly after adding the new elevator. The new elevator operates smoothly without abnormal noise and requires minimal maintenance. The system output increased easily by 30 t/h. The power consumption per ton of cement dropped from 34.0 kWh/t before the retrofit to 29.8 kWh/t.

This retrofit not only achieved economic benefits from increased production and reduced consumption but also delivered social benefits through reduced CO2 emissions associated with lower electricity usage.