粉塵爆発 は、空気中に浮遊する可燃性粉塵粒子が特定の条件下で酸素と反応し、極端な熱と圧力を放出することで発生します。これらの危険を軽減するために、産業界は 防爆型集塵機 を満たすように設計されています。 アテックス そして NFPA規格.

粉塵爆発の条件

のためには、4つの重要な要素が揃う必要があります。 粉塵爆発の危険性 が発生します:

可燃性粉塵 (雲を形成するのに十分小さい)。

酸化剤 (通常は酸素)。

点火源 (火花、高温の表面など)。

閉鎖空間 (集塵機のバグハウスなど)。

集塵機の防爆対策

主な目的は、初期段階での爆発を抑制し、内圧を以下のレベルに保つことです。 100kPa.よく設計された 防爆型集塵システム を含みます:

1.効果的な予防策

ほこりの蓄積を防止 パイプや機器の

発火源の管理 (裸火、溶接火花、静電気放電は避けてください)。

不活性ガスの使用 (窒素など)で酸素濃度を下げる(一般的な ATEX認定集塵機).

2.爆発安全構造設計

集塵機のホッパーは、堆積を防ぐために 70° 以上の傾斜が必要です。

湿度による閉塞を避けるため、ヒーターエレメントを設置してください。

気流調整バルブがチャンバー間の圧力バランスを調整(変動<5%)。

3.防爆コンポーネントと接地

防爆仕様のパルスバルブと電気部品が火花のリスクを排除します。

適切な接地は静電気の蓄積を防ぎます(NFPA 652準拠のために重要)。

4.静電気保護

導電性繊維(ステンレススチールなど)が埋め込まれた帯電防止フィルターバッグは、静電気を安全に排出します。

5.火災・爆発検知システム

COモニタリングと温度センサーがアラームを作動。

危険度の高いゾーンには自動消火装置(CO₂または窒素)。

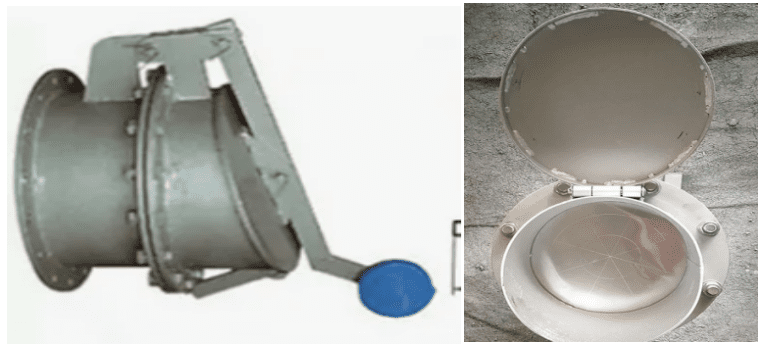

6.爆発ベントの設計

爆発ベント膜またはラプチャーディスクは5~10kPaで圧力を放出します。

通気面積の計算は、Kst 値ガイドラインに従ってください ( 比率は通常 1:5 ~ 1:50 対コレクタ容積 )。

ATEX/NFPAC認定集塵機の主要コンポーネント

1.帯電防止フィルター材料

導電性フィルターバッグ(炭素繊維混紡など)は、静電気スパークを防止します。

2.防爆型パルスバルブ

密閉型電磁弁と一体型防爆アセンブリの2種類。

3.消火システム

- CO₂・窒素注入で火災を自動抑制。

結論

防爆設計の原則を導入することで、産業界はATEX指令やNFPA 652規格に準拠し、粉塵爆発のリスクを大幅に低減することができます。

ATEX認定集塵機をお探しですか? お問い合わせ お客様の施設のニーズに合わせたカスタム防爆ソリューションを提供します。