Since the commissioning in May 2007, Company A’s cement pre-grinding system has faced frequent failures with the roll press. These issues include low and unstable working pressure on both sides, improper adjustment of the material distribution valve, large particle size of the material exiting the roll press, low hourly output, high grinding energy consumption, and poor overall economic efficiency. This article will share our experiences and improvement measures in controlling the roll press.

Problem 1: Uneven Material Distribution Causing Pressure Fluctuations

Root Cause:

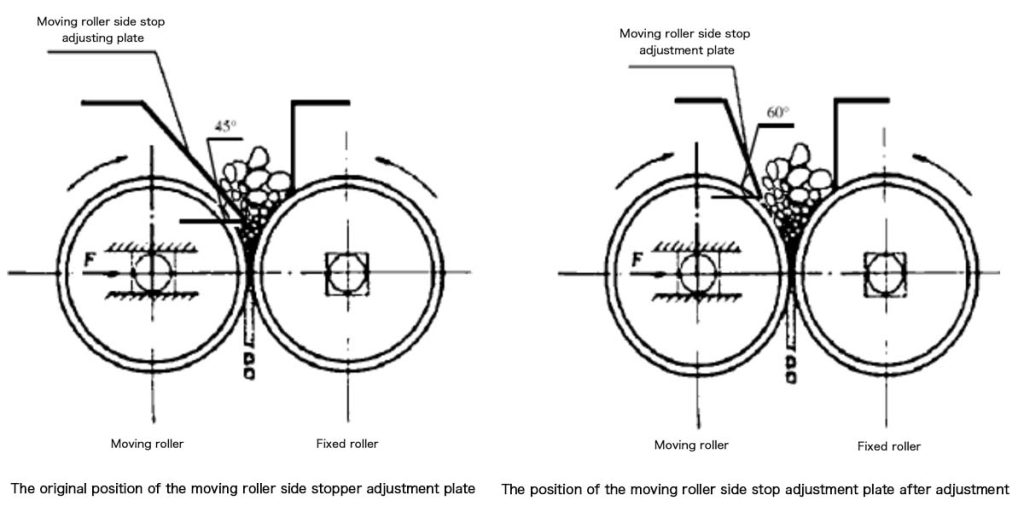

Material guide plate misalignment (45° angle toward fixed roller)

80% material flow biased to fixed roller side

Moving roller side starvation → pressure instability

Solution:

Repositioned guide plate to 60° angle facing moving roller exterior

Set initial roller gap to 10mm for optimal material bed formation

Result: Balanced flow distribution → pressure stabilized within 72 hours

Problem 2: Low Hydraulic Pressure (6.0MPa vs Required 8.2MPa)

Diagnosis:

Initial system pressure set at 6.0MPa (below threshold)

Hydraulic pumps couldn’t compensate for roller gap expansion

Fix:

Increased initial pressure to 6.5MPa

Stabilized feed rate at 220±5 t/h

Outcome:

Working pressure reached 8.2-8.6MPa

Crushing ratio improved from 4.09 to 10.10

Data Spotlight:

| Parameter | Before | After | Change |

|---|---|---|---|

| Working Pressure | 7.4MPa | 8.6MPa | +16.2% |

| Power Draw | 42kW | 35kW | -16.6% |

Problem 3: Material Distribution Valve Misconfiguration

Mistake:

Valve opening set at 20% → edge material buildup

Coarse particles (~10mm) in finished product

Correction:

Adjusted valve opening to 23%

Cleared edge chutes every 4 hours

Verification:

No more material accumulation

Particle size distribution:

5mm: 0% (previously 12%)

<2mm: 89% (previously 63%)

Before/After Performance Comparison

| KPI | Pre-Fix | Post-Fix | Improvement |

|---|---|---|---|

| Avg. Particle Size | 3.81mm | 1.54mm | 59.6% |

| System Output | 100% | 113.1% | +13.1% |

| Energy Consumption | 100% | 83.4% | 16.6% |

Why These Solutions Work

1.Mechanical Advantage

60° guide plate angle optimizes material trajectory

6.5MPa initial pressure builds sufficient hydraulic force

2.Process Synergy

Valve opening at 23% balances throughput & grinding efficiency

Regular edge chute cleaning prevents recirculation

Maintenance Pro Tips

🔧 Monthly Checks:

Laser-align roller parallelism (tolerance <0.1mm/m)

Test hydraulic accumulator precharge pressure

⚠️ Red Flags:

Pressure fluctuations >±0.3MPa → Check feed consistency

Sudden power spikes → Inspect bearing lubrication

Key Improvements Achieved

✅ +13.1% hourly output – Ball mill production increase

✅ 59.6% finer particles – Avg. size reduced from 3.81mm to 1.54mm

✅ 16.6% energy savings – Lower grinding power consumption

✅ Stable 8.6MPa pressure – Up from fluctuating 7.4-7.8MPa

If you face similar issues, please feel free to contact us. We are happy to help!