Overview of An Air slide

Overview of An Air slide

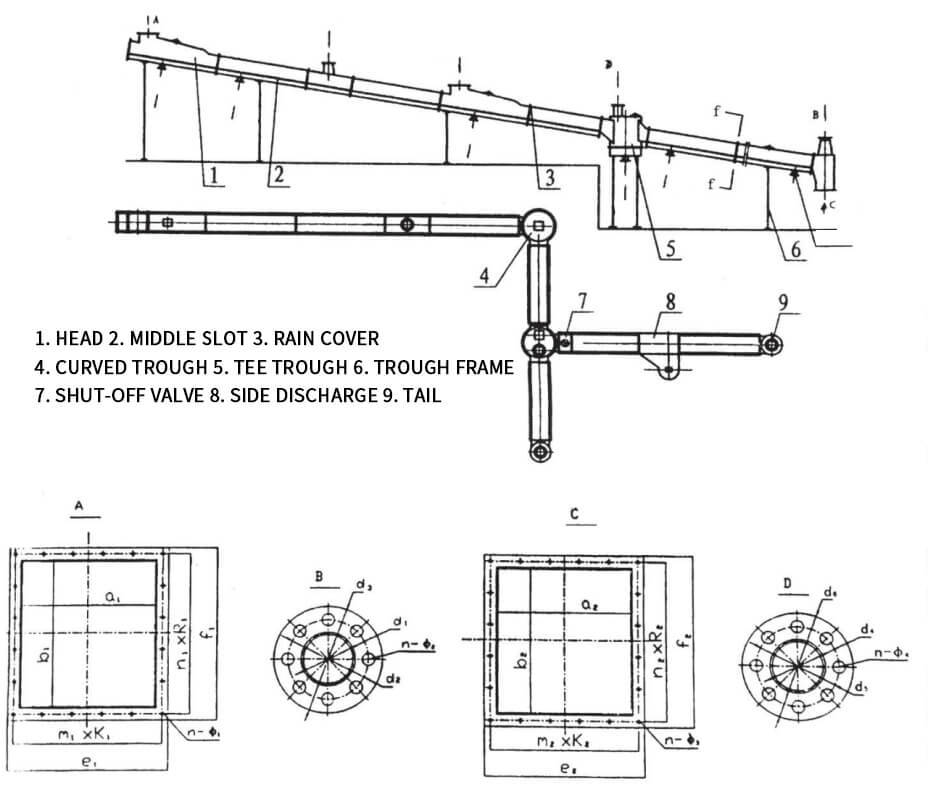

The cement air slide conveyor is a pneumatic conveying equipment widely used to convey dry powdery materials.

It is commonly used in the cement industry to transport cement and raw meal powder.

The air slide conveyor requires no rotating parts to convey materials, making it easy to maintain. Its design ensures good sealing, minimizes noise, and provides safe and reliable operation. It consumes less power and allows for convenient changes in conveying direction. Additionally, it supports multi-point feeding and multi-point discharge, making it widely applicable.

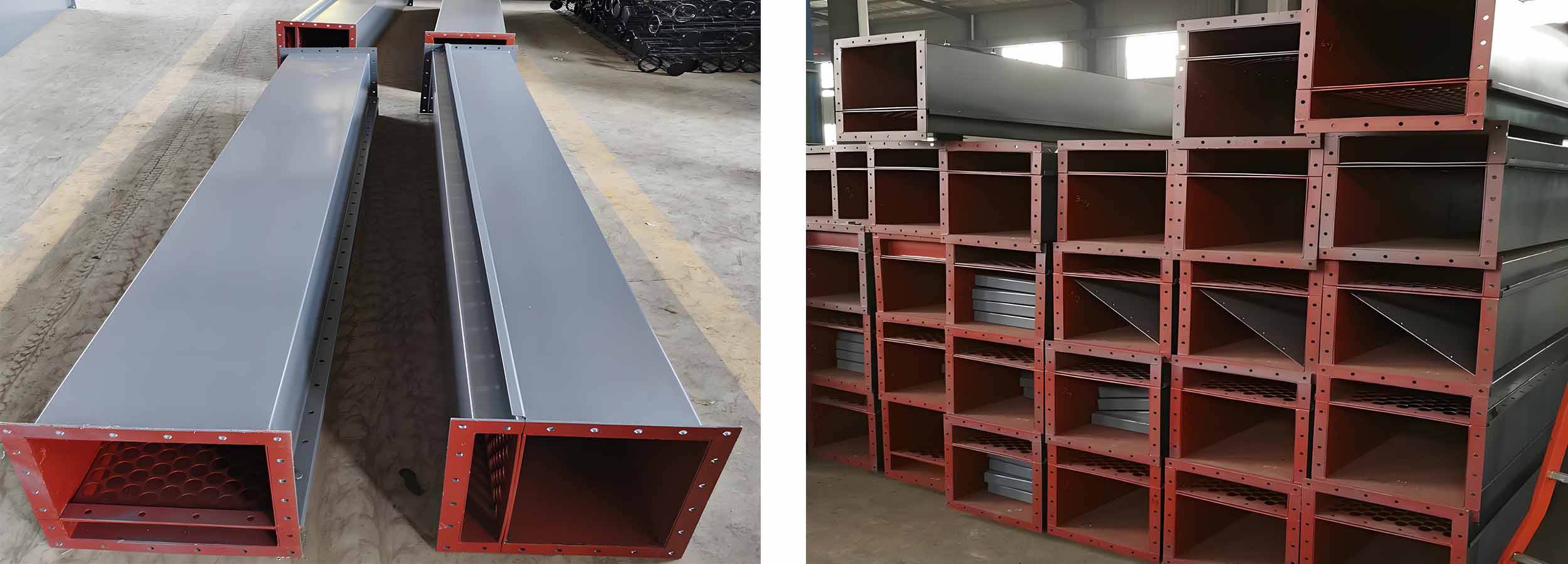

The main components of the air slide conveyors are the tank body and the breathable layer.

This series of products uses PETS-6 (polyester) type synthetic fiber fabric as the breathable layer.

It is a new type of breathable type.

It has high temperature resistance (can exceed 150°C) and corrosion resistance , wear resistance, low hygroscopicity, light weight , smooth surface, long service life and other advantages.

Our air slide conveyor is a highly efficient material conveying equipment that uses airflow to assist material movement and reduces dust generation. To further improve the overall efficiency of the system, you can consider using our pulse jet bag filter, which can effectively capture fine particles in the air to ensure a clean working environment.

Technical performance

1. Conveyed materials: dry powdery materials with moisture content ≤1% and temperature 150℃

2. Conveying capacity:

| Spec. | XZ200 | XZ250 | XZ315 | XZ400 | XZ500 | XZ630 | XZ800 | ||||

| Conveying capacity | WIDTH | mm | 200 | 250 | 315 | 400 | 500 | 630 | 800 | ||

| a=4° | Cement | t/h | 22 | 40 | 70 | 130 | 220 | 320 | 400 | ||

| Raw material | 16 | 30 | 55 | 100 | 165 | 245 | 310 | ||||

| a=6° | Cement | 40 | 65 | 120 | 250 | 400 | 610 | 765 | |||

| Raw materia | 30 | 55 | 90 | 185 | 300 | 455 | 565 | ||||

| a=8° | Cement | 50 | 80 | 140 | 300 | 470 | 720 | 900 | |||

| Raw material | 35 | 65 | 110 | 225 | 355 | 540 | 670 | ||||

| a=10° | Cement | 60 | 100 | 170 | 380 | 570 | 900 | 1080 | |||

| Raw material | 45 | 80 | 140 | 285 | 425 | 670 | 800 | ||||

| a=12° | Cement | 70 | 120 | 205 | 455 | 685 | 1080 | 1295 | |||

| Raw material | 50 | 95 | 165 | 340 | 510 | 805 | 960 | ||||

| Length of groove body | Standard part | mm | 2000 | ||||||||

| Nocvstandard part | mm | nX250 | |||||||||

| Needed wind pressure | KPa | 4-5.5 | |||||||||

| Transparent layer | Needed air volume | mVfn* min | 1.5-2 | ||||||||

| Material | synthetic fibre | ||||||||||

| Thickness | mm | 4-6 | |||||||||

| Temperature resistance; | V | 150 | |||||||||

| RIffilSgth, | N/cm (width) | 4700 | |||||||||

| Resistance | Pa | 800-1200 (on the condition of 2m3/m2.min) | |||||||||

Airslide conveyor systems: the preferred choice of industry

The airslide conveyor system is the preferred choice for many industries because of its:

- Reliable

- Durability

- Economical

This pneumatic conveying equipment makes it an ideal choice for transporting bulk powders applications such as:

- In-plant conveying that feed to storage or processes

- Loadout from bulk silos to trucks, rail cars or barges

- Storage silo and bin withdrawal

- Distribution from bucket elevators to storage silos

- Gathered under baghouses or precipitators

You May Also Like

|  |  |

|  |  |

Darko is among the fabric filters manufacturers in China. We have been supplying small and large companies with safe and ISO-certifed fabric filters wholesale. We provide industrial fabric filters of various specifications an custom sizes.

Darko has been working as a trust worthy fabric filter manufacturer and supplier in China for more than 10 years. With our years of experience in the industry, we can guarantee the production of high-quality Chinese fabric filters. Aside from manufacturing facilities in our own factory we also offer customization and design services to our customers. We produce fabric filters to process various air volume .

If you are looking for a filter company, you can rely on Darko. Buy fabric filters in bulk from us and let us help you grow your business using our customizable and affordable products.