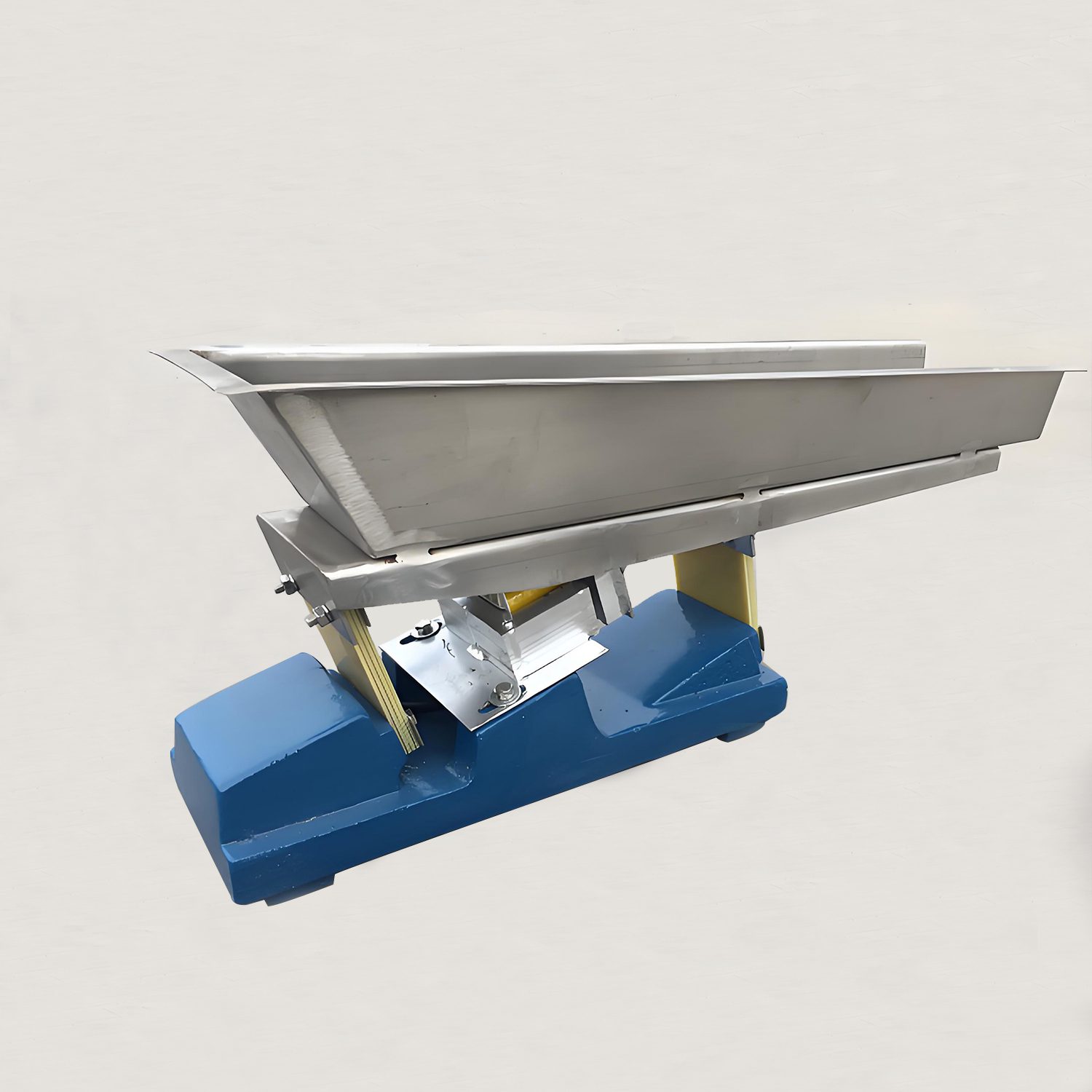

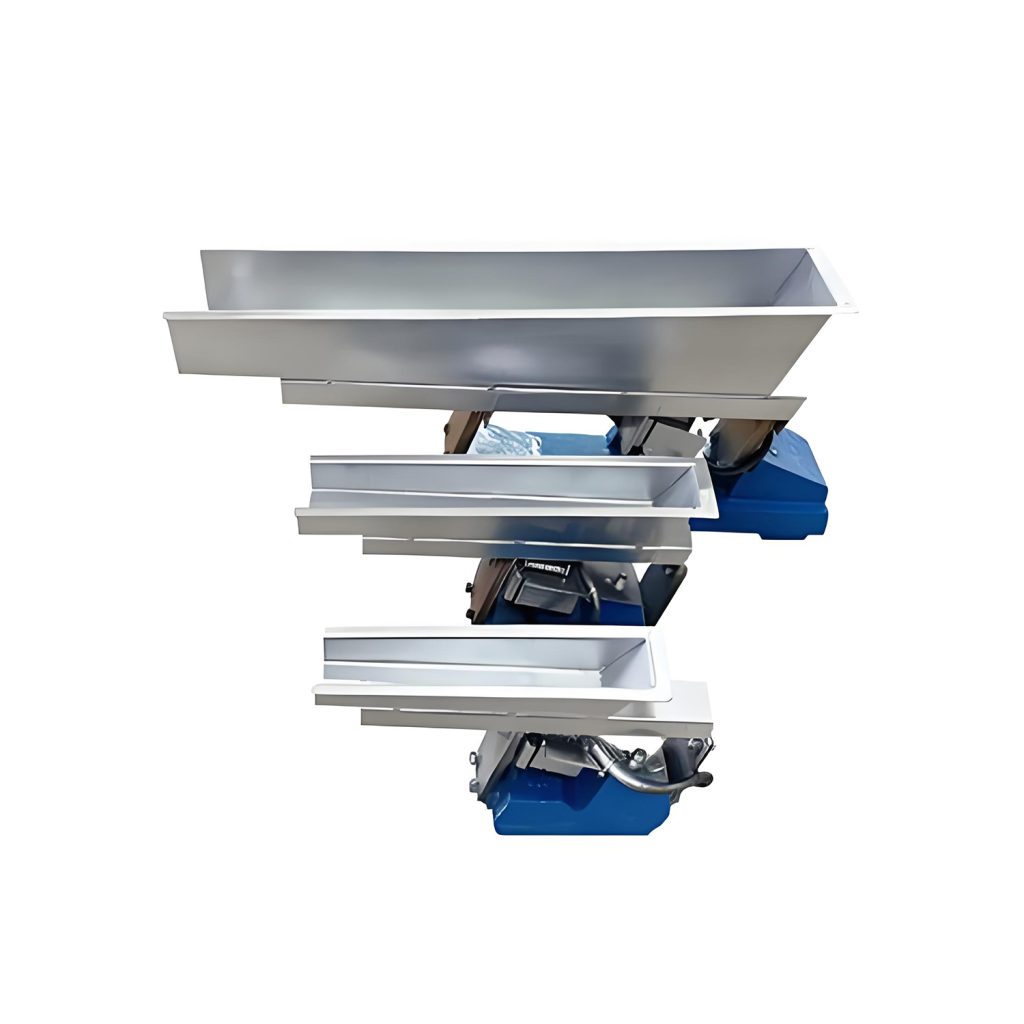

How does a electromagnetic vibration feeder work?

The micro electromagnetic vibration feeder utilizes electromagnetic force to generate vibrations, thereby enabling the transportation and metering of materials. Specifically, when the electromagnet is energized, it creates a magnetic field that causes the core to vibrate due to magnetic force. Furthermore, by adjusting the current and frequency of the electromagnet, one can control the amplitude and frequency of the vibrations, which allows for precise control of the material flow.

What can Darko offer?

Darko specializes in the production of small electromagnetic vibration feeders. Moreover, we offer high efficiency, with a 100% quality guarantee, and can customize to meet your needs. Thus, you can trust us to deliver the perfect solution for your requirements.

Host selection

| type | Productivity calculation test weight(t/m3) |

use |

| GZV open type | 1.6 | Material feeding without special requirements |

| GZVF closed type | 1.6 | Feeding of dusty and volatile materials |

Technical Parameters

| model | GZV0.5 | GZV1 | GZV1F | GZV2 | GZV2F | GZV3 | GZV3F | GZV4 | GZV4F | GZV5 | GZV5F | GZV6 |

production capacity t/h |

0.15 |

0.1 |

0.5 |

1 |

2 |

4 |

6 | |||||

| double amplitude mm | 1.5 | |||||||||||

Number of vibrations r/min |

3000 | |||||||||||

Supply voltage V | 220 | |||||||||||

| current A | 0.06 | 0.08 | 0.12 | 0.15 | 0.2 | 0.25 | 0.3 | |||||

Active power W | 3.5 | 5 | 8 | 20 | 25 | 30 | 50 | |||||

weight kg | 4.3 | 4.5 | 5.5 | 7 | 8 | 12 | 14 | 18 | 21 | 27 | 30 | 45 |

Key features

Efficiency:

The micro electromagnetic vibration feeder is driven by electromagnetic force, featuring a fast response speed, large vibration amplitude, and high transportation efficiency, significantly enhancing production line efficiency.

Precision:

By adjusting the current and frequency of the electromagnet, the feeder achieves precise control over the material flow rate, ensuring accuracy and stability in the production process.

Reliability:

The micro electromagnetic vibration feeder has a simple structure and is easy to maintain. It is made from high-quality materials and manufacturing processes, ensuring the stability and durability of the equipment.

Wide Applicability:

This feeder is suitable for transporting and metering various powders, granules, and flakes. It is widely used in industries such as chemicals, food, pharmaceuticals, and metallurgy.

Applications

The micro electromagnetic vibration feeder is widely applied in various production lines, including chemical, food, and pharmaceutical production lines. In these settings, it enables precise metering and transportation of materials, ensuring stability in the production process and consistency in product quality. Additionally, the micro electromagnetic vibration feeder features automation and intelligence, allowing it to interact with other equipment on the production line for automated control and production.

Daily maintenance

To ensure the normal operation of the micro electromagnetic vibration feeder and extend its service life, regular maintenance and care are necessary.

Specific maintenance tasks include:

1. Regularly cleaning the surface and interior of the equipment to keep it clean and hygienic.

2. Periodically checking the tightness of the fasteners; if any are loose, they should be tightened promptly.

3. Regularly inspecting the operation of the electromagnet and vibration components; any abnormalities should be addressed immediately.

4. Periodically lubricating and servicing the equipment to ensure normal operation and prolong its lifespan.

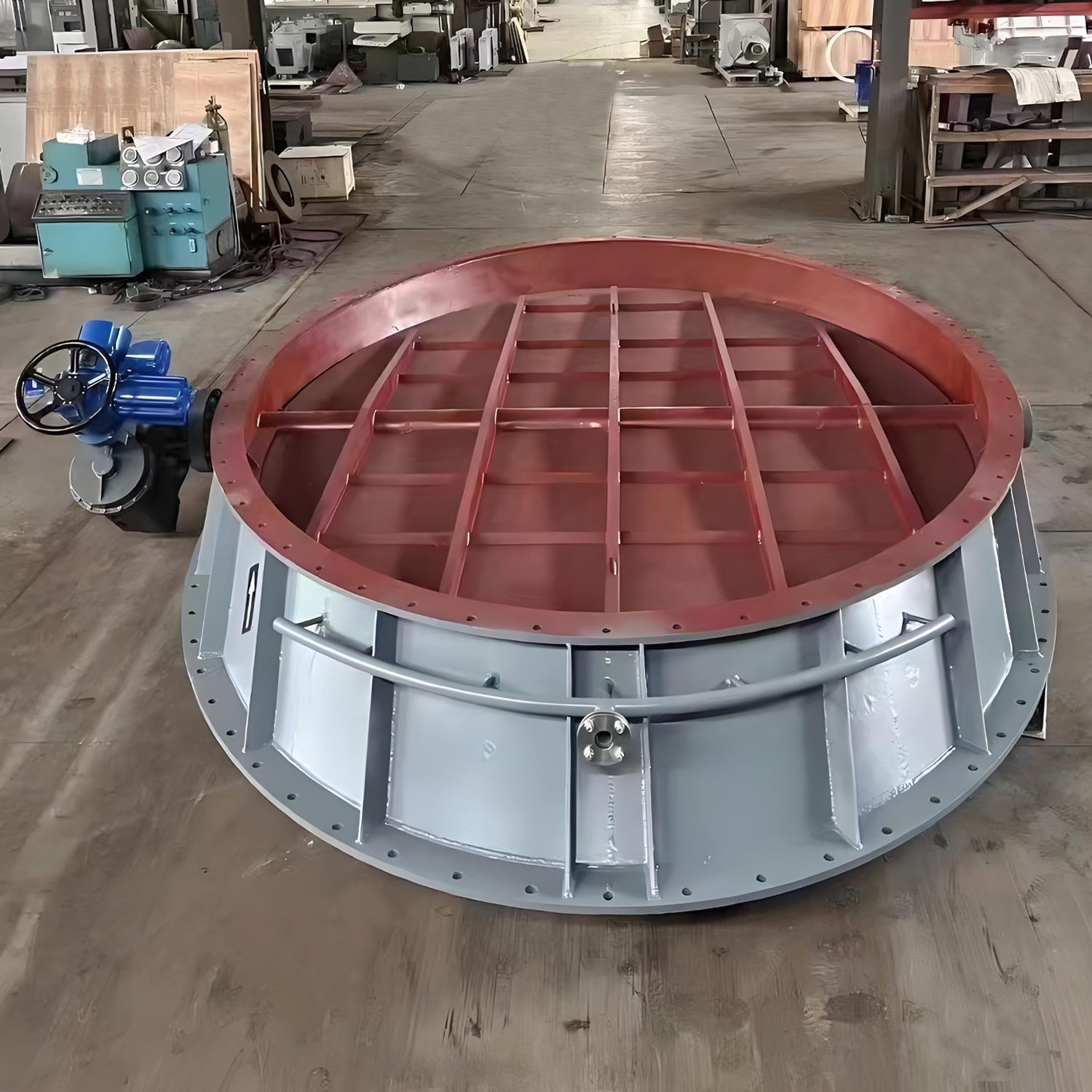

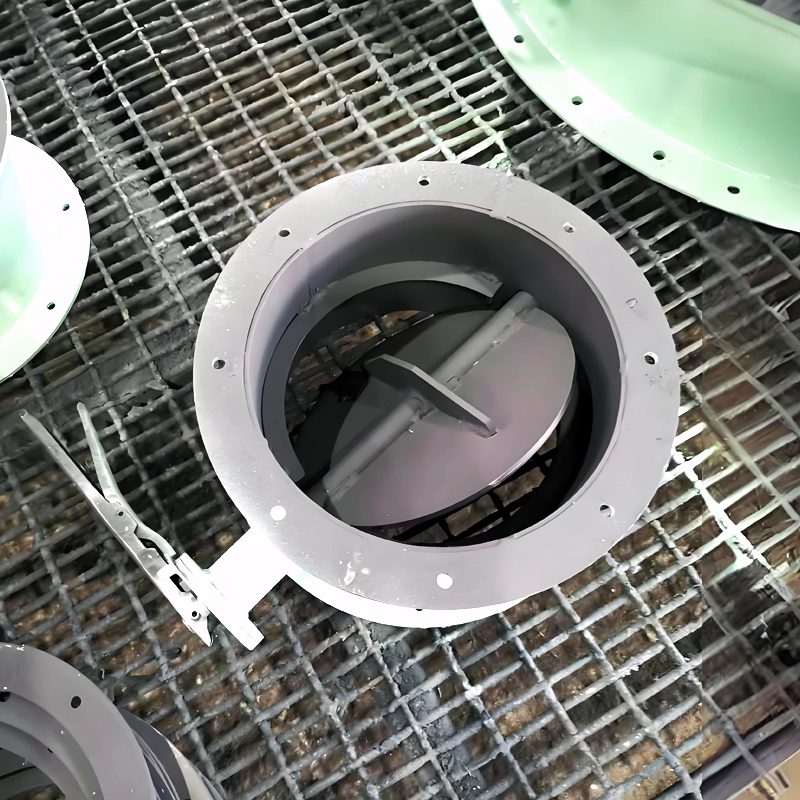

You may also like

|  |  |

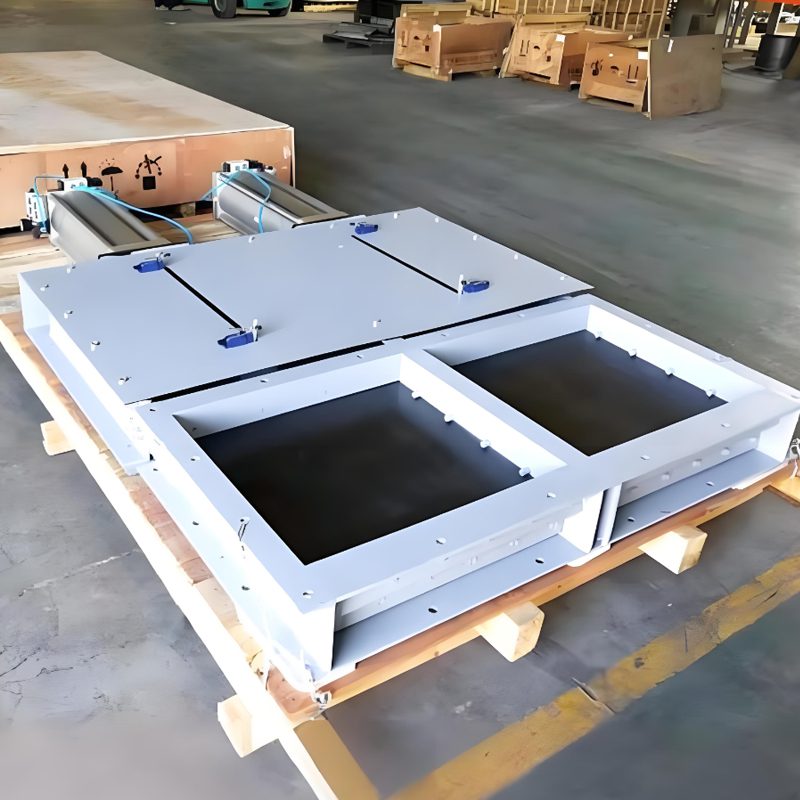

| Manual gate valve |  |  |