Air Pollution Control Device

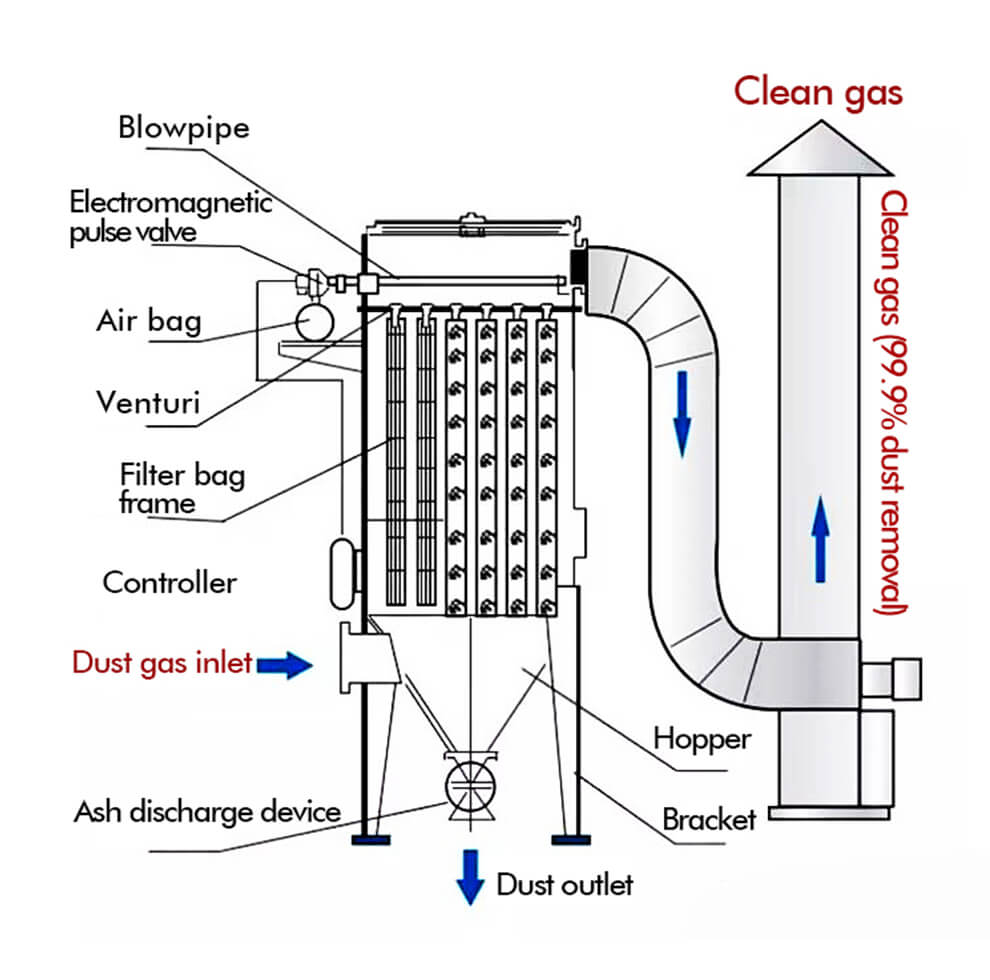

The working principle of a uni air filter mainly includes the following steps:

- Air Inlet

Dust-laden gas enters the dust collector through the inlet.

- Filtration

The gas passes through a filter (like bags or cartridges). And the filter captures particles on the surface or within the filter. Then the filtration process can involve mechanisms such as inertial collision, sedimentation, and electrostatic attraction.

- Dust Cleaning

When dust accumulates on the filter material to a certain extent, it can affect the dust removal efficiency. At this point, a dust cleaning device removes the dust. This restores the filtering capacity of the material.

- Discharge of Purified Gas

The filtered clean gas is discharged through the outlet, achieving the purpose of air purification.

- Dust Collection

The removed dust is collected in a hopper, which is regularly cleaned or disposed of.

Darko uni air filter design concept

“Nano” coated FEMES filter bag

Darko Environmental’s special nano-coated filter bag outperforms ordinary ones. It has a higher filtration accuracy and can resist temperatures up to 240°C. Its performance is 20% better, and its corrosion resistance is 30% better. This saves you consumables, cuts costs, and extends its life. It also cleans more thoroughly.

0.5μm filtration accuracy

The filtration accuracy of 0.5μm smoke particles reaches more than 99%.

Pulse cleaning

Fully automatic pulse cleaning provides high-quality cleaning effect and increases the life of the filter material.

ASCO pulse valve

The spray life is more than 2 million times, the failure rate is low, and the later use cost is reduced.

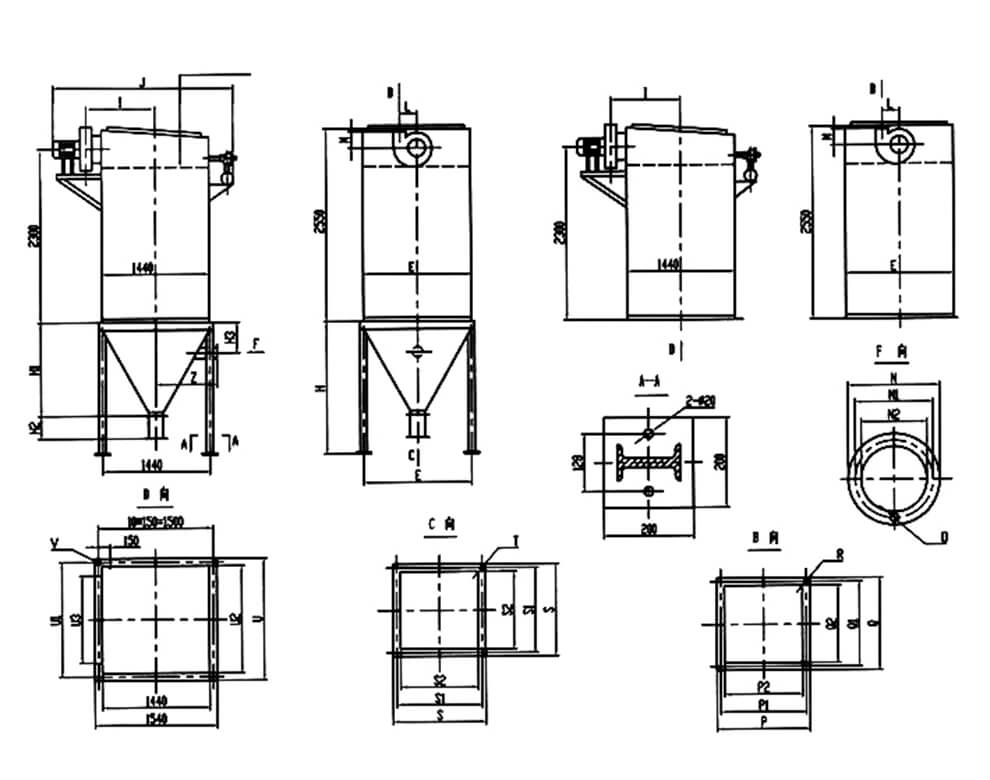

Uni air filter design drawing

Technical Parameters

| PerformanceModel | HMC-32 | HMC-48 | HMC-64 | HMC-80 | HMC-96 | HMC-112 | |

| Processing air volume(m3/h) | 1500-2100 | 2100-3200 | 2900-4300 | 4000-6000 | 5200-7000 | 6000-9000 | |

| Total filter area(m2) | 24 | 36 | 48 | 60 | 72 | 84 | |

| Filter wind speed(m/min) | 1.00-1.50 | 1.00-1.50 | 1.00-1.50 | 1.10-1.70 | 1.20-1.70 | 1.20-1.80 | |

| Number of filter bags (bars) | 32 | 48 | 64 | 80 | 96 | 112 | |

| Inlet gas temperature (℃) | ≤120℃ | ||||||

| Dust collector resistance (Pa) | ≤1200 | ||||||

| Import dust concentration (g/m3) | <200 | ||||||

| Import emission concentration (mg/m3) | ≤100 | ||||||

| Compressed air for cleaning | Pressure(Pa) | 5~7×10⁵ | |||||

| Air consumption (m3/min) | 0.10 | 0.14 | 0.20 | 0.24 | 0.29 | 0.34 | |

| Withstand negative pressure (Pa) | 5000 | ||||||

| Pulse valve quantity (pieces) | 4 | 6 | 8 | 10 | 12 | 14 | |

| Fan motor power (KW) | 1.5 | 3.0 | 3.0 | 5.5 | 5.5 | 7.5 | |

| Weight(kg) | Type A (with ash hopper) | 1350 | 1620 | 1850 | 2360 | 2800 | 3200 |

| Type B (without ash hopper) | 1220 | 1470 | 1670 | 2150 | 2540 | 2880 | |

Benefits of Uni air filter

The uni air filter is popular in cement industrial and other environmental protection fields.

- Compact Size

Its compact design makes it suitable for space-constrained environments.

- Easy Installation

The simple structure allows for easy installation and maintenance.

- User-Friendly Operation

High automation levels make it easy to operate, with low training requirements.

- High Filtration Efficiency

Effectively captures fine particles, improving air quality.

- Strong Flexibility

Configurations can be adjusted based on needs, adapting to different operating conditions.

- Low Cost

Relatively low investment and operating costs make it economical and practical.

- Low Energy Consumption

Minimal energy usage during operation contributes to energy savings and emissions reduction.

Customer buy Uni air filter usually also purchase

Darko has over ten years of in-depth industry experience. The company has accumulated rich industry expertise. Darko provides clients with one-stop equipment solutions, including project communication, on-site surveys, design and development, production, transportation, and installation services throughout the entire process.

Our clients typically require complete sets of customized filtration devices. Having a complete set of bag fiter equipment can save considerable time and effort in matching devices during operations, thereby enhancing production efficiency. Complete bag fiter equipment sets are manufactured by the same producer, ensuring consistent specifications for all components and avoiding compatibility issues that may arise between different brands. This reduces the failure rate of the equipment and helps maintain stable production quality.

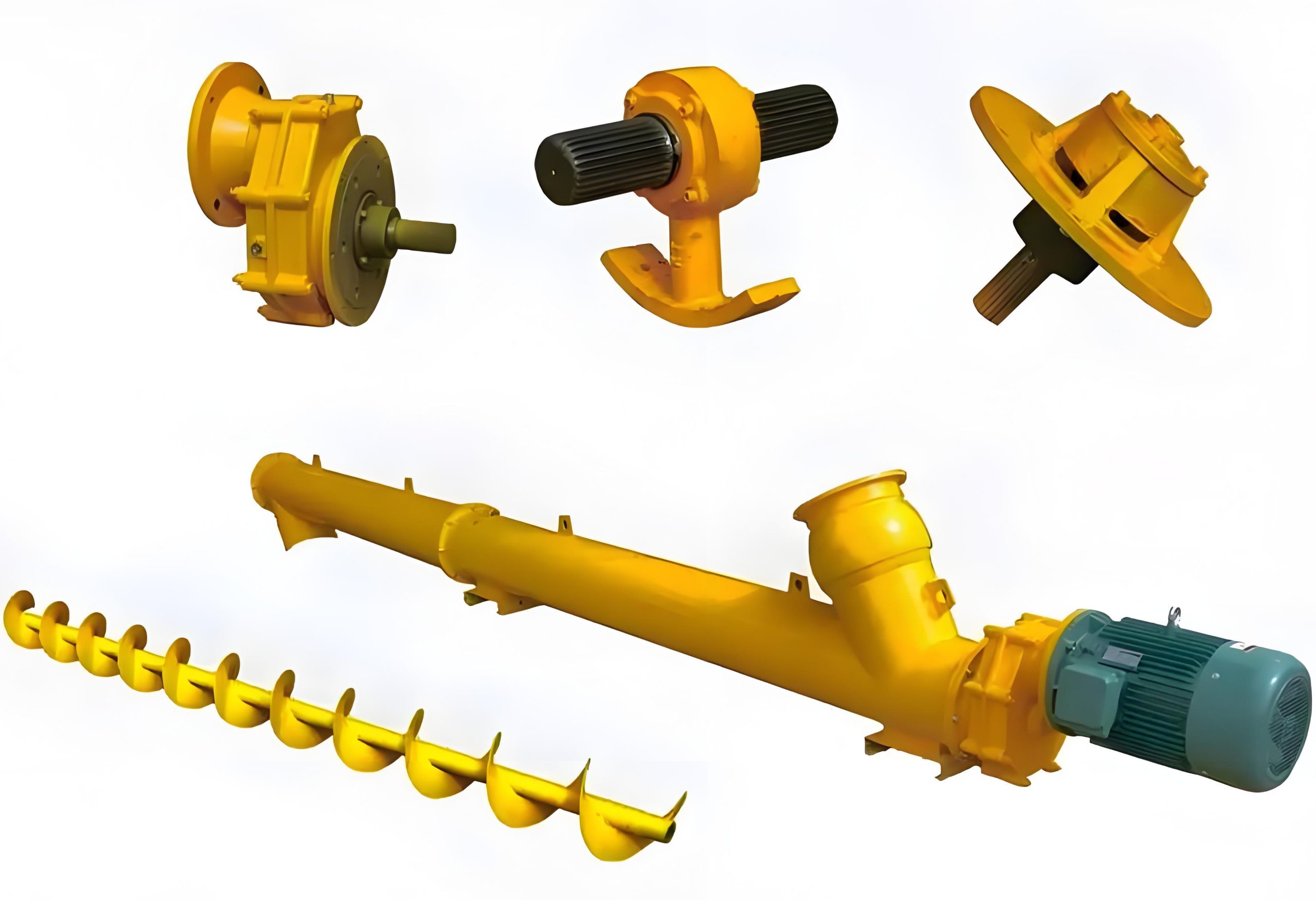

The U-shaped screw conveyor features easy cleaning, convenient maintenance, and good thermal insulation.

The U-shaped screw conveyor features easy cleaning, convenient maintenance, and good thermal insulation.  An auger conveyor has the capacity ranges from 1 to 100 tons/hour. It’s speed can range from 30 to 300 RPM. Darko accepts customization

An auger conveyor has the capacity ranges from 1 to 100 tons/hour. It’s speed can range from 30 to 300 RPM. Darko accepts customization

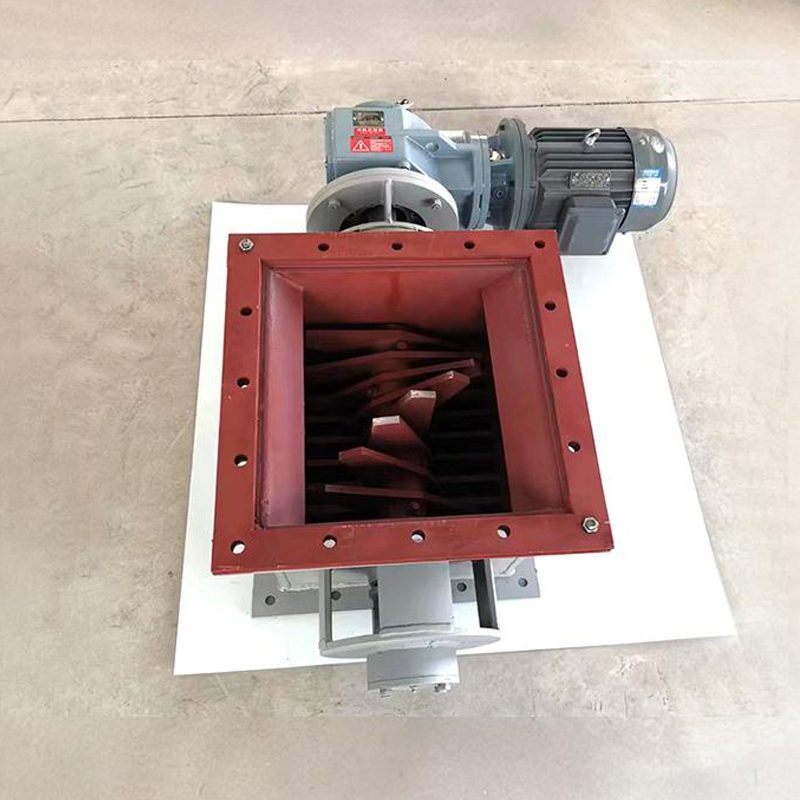

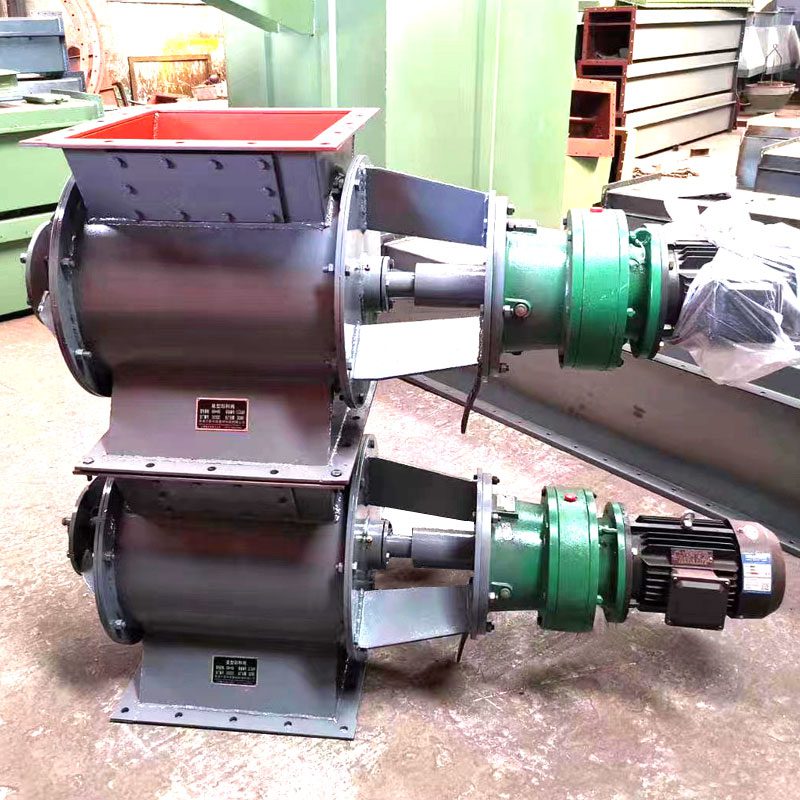

Dako designs and produces the rotary valve . This feeder is mainly used in the pneumatic conveying process . It is efficient and stable .

Dako designs and produces the rotary valve . This feeder is mainly used in the pneumatic conveying process . It is efficient and stable .