Высокоэффективный бетон появился благодаря изменениям в гранулометрическом составе, вызванным технологией измельчения. В современном обществе это мощный инструмент для развития строительства. Это не только важный строительный материал, но и цементная паста. Плотность этой пасты варьируется в зависимости от размера частиц и свойств цемента. Следовательно, мы можем изменять характеристики цемента, например, размер его частиц, что является ключевым фактором для изменения его характеристик. Однако плотность упаковки частиц цемента напрямую связана с развитием современных технологий измельчения. Эта связь привела к экспериментам по изучению размера частиц цемента. Теперь мы изучаем различные характеристики частиц, чтобы сделать цемент более подходящим для наших строительных нужд. Эти усилия представляют собой наше стремление к совершенствованию и прогрессу.

01 Анализ распределения частиц цемента по размерам

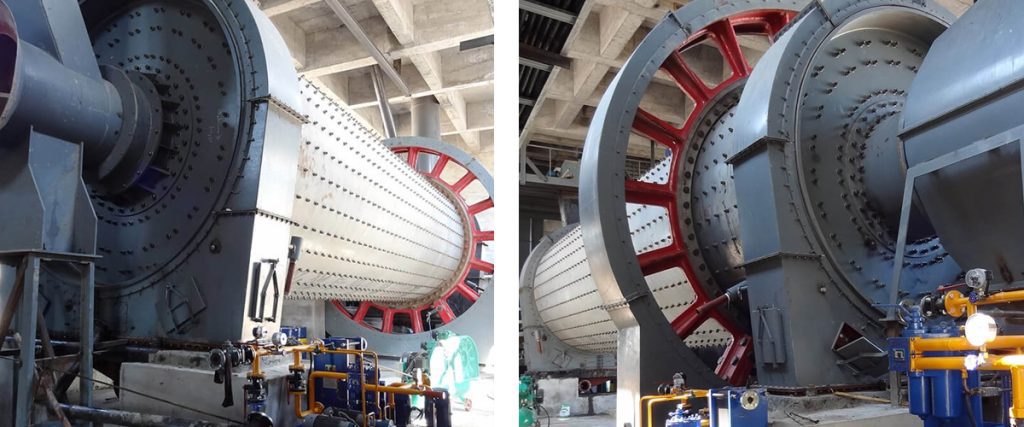

В качестве объекта исследования мы выбрали четыре новых процесса измельчения цемента:

Валковый пресс + V-образный сепаратор + открытая цепь шаровая мельница

Валковый пресс + V-образный сепаратор + шаровая мельница закрытого типа

Вертикальная мельница как процесс окончательного измельчения

Вертикальная мельница + шаровая мельница закрытого типа

Мы измерили тонкость с помощью ситового анализа и использовали выражение Розина-Раммлера-Беннета для расчета коэффициента однородности и характерного размера частиц. Это помогло нам проанализировать распределение частиц по размерам. Мы также использовали лазерный анализатор размера частиц для дальнейших измерений.

Результаты исследования показывают:

(1) Распределение частиц цемента, полученного в результате этих четырех процессов, более равномерно, чем при использовании традиционных шаровых мельниц открытого цикла. Процесс "валковый пресс + V-образный сепаратор + шаровая мельница открытого цикла" позволяет контролировать однородность благодаря взаимодействию компонентов. Дальнейшие испытания показали, что равномерное распределение частиц помогает контролировать вязкость и прочность цемента. Таким образом, это позволяет лучше контролировать использование цемента и его эффективность.

(2) Эти четыре процесса повышают эффективность использования цемента. Механическое измельчение изменяет свойства цемента, что дает этим процессам хорошие перспективы использования и развития.

(3) Добавление системы предварительного измельчения (валковый пресс + V-образный сепаратор) к традиционному помолу в шаровой мельнице уменьшает разницу в распределении частиц по размерам между системами открытого и закрытого цикла. Она уточняет характеристики цемента и сочетает старые и новые формулы для более выраженного эффекта. Это увеличивает срок службы и создает хорошие перспективы развития.

(4) Продукт, полученный в вертикальной мельнице в качестве конечного процесса измельчения, имеет распределение частиц по размерам, аналогичное системам, сочетающим валковый пресс или вертикальную мельницу с шаровой мельницей.

02 Результаты исследований

При смешанном помоле летучая зола (которая легко размалывается) концентрируется в более мелких частицах, а шлак (который труднее размолоть) концентрируется в более крупных частицах. Это приводит к снижению плотности упаковки сухого порошка. При раздельном помоле получается цемент с меньшим содержанием крупных и немного недостаточным содержанием мелких частиц. Увеличение удельной поверхности смешанных материалов значительно влияет на распределение частиц и повышает плотность упаковки сухого порошка.

Существует хорошая корреляция между гранулометрическим составом и плотностью упаковки в цементной пасте. По мере увеличения коэффициента однородности частиц плотность упаковки в пасте линейно уменьшается. При смешанном помоле паста с летучей золой имеет более высокую плотность упаковки, а паста со шлаком - более низкую. При раздельном помоле увеличение удельной поверхности смешанных материалов значительно улучшает плотность пасты.

Когда содержание смешанного материала фиксировано, более высокая плотность упаковки в пасте приводит к повышению прочности. Сравнение двух методов измельчения:

Для цемента с летучей золой, измельченного отдельно при удельной площади 400 м²/кг, прочность ниже, чем у смешанного помола с тем же содержанием.

Для цемента со шлаком раздельное измельчение дает лучшую прочность, чем смешанное.

Кроме того, цемент с летучей золой хуже совместим с добавками, чем цемент со шлаком. С увеличением содержания смешанных материалов возрастает потребность в воде для получения стандартной консистенции, значительно увеличивается время схватывания и уменьшается количество химически связанной воды при различном возрасте. В целом, отдельно измельченный цемент обладает лучшими механическими свойствами, а цемент со шлаком работает лучше, чем цемент с летучей золой.

03 Применение молотого цемента в повседневной жизни

Цемент - жизненно важный строительный материал, но его производство потребляет значительное количество энергии. Сегодня, когда приоритетными задачами являются энергосбережение и сокращение выбросов, минимизация энергопотребления при получении высокоэффективных продуктов имеет решающее значение.

Гранулометрический состав цемента - ключевой фактор, влияющий на его характеристики. Оптимизация этого распределения позволяет улучшить характеристики цемента и удовлетворить спрос на производство цемента с низким энергопотреблением. Два важных аспекта - это распределение по различным диапазонам размеров частиц и общая упаковка частиц.

В данном исследовании изучены оба аспекта. Исходя из этого, мы оптимизировали распределение частиц цемента по размерам и предложили новую модель для первоначальной плотной упаковки цементных частиц. Исследование развития прочности при различных размерах частиц показывает, что прочность возникает в результате срастания, соединения и гидратации цементных частиц и продуктов их жизнедеятельности, что создает сопротивление внешним силам.

Размер частиц цемента напрямую связан со скоростью и степенью гидратации. Частицы разного размера гидратируются с совершенно разной скоростью. Среди всех частиц, частицы размером 3-32 мкм доминируют в развитии прочности. Распределение в этом диапазоне должно быть непрерывным, с общим содержанием не ниже 65%. Дальнейшие исследования показывают, что частицы размером 16-24 мкм особенно важны - чем больше, тем лучше.

Частицы размером менее 3 мкм гидратируются очень быстро, некоторые даже во время смешивания, поэтому они приносят пользу только на ранних этапах набора прочности. Частицы размером 32-60 мкм имеют низкую степень гидратации, а частицы размером более 60 мкм обладают минимальной активностью и действуют в основном как наполнитель. Таким образом, большее содержание частиц размером более 32 мкм означает меньшее использование клинкера и худшие характеристики цемента.

Изучение развития силы показывает:

Частицы в диапазоне (0, 3) мкм быстро набирают прочность, но не достигают наивысшей 3-дневной прочности. Их прочность может даже уменьшиться через 28 дней. Их содержание должно быть ограничено, в идеале - ниже 10%.

Частицы в диапазоне (3, 16) мкм обеспечивают самую высокую 3-дневную прочность.

Частицы в диапазоне (16, 32) мкм обеспечивают самую высокую 28-дневную прочность.

В целом, частицы в диапазоне (3, 32) мкм имеют решающее значение для развития прочности - чем больше, тем лучше. Частицы в диапазоне (32, 64) мкм вносят незначительный вклад в раннюю прочность, но их долгосрочная прочность (через 180 дней) догоняет или даже превосходит прочность частиц в диапазоне (3, 32) мкм. Для развития долгосрочной прочности этот диапазон очень важен, в идеале - не менее 10%.

Частицы размером более 64 мкм очень медленно набирают силу. Их содержание должно быть ограничено, в идеале - ниже 5%. Теоретический анализ и экспериментальные результаты подтверждают, что фрактальная размерность является подходящим характеристическим параметром для распределения частиц по размерам. Он хорошо коррелирует с другими параметрами.

В заданных экспериментальных условиях:

При индексе однородности n=1, по мере увеличения характерного размера частиц X с 16 мкм до 32 мкм, фрактальный размер D уменьшился с 2,50 до 2,27.

При характерном размере частиц X=29 мкм, когда индекс однородности n увеличился с 0,6 до 2,2, фрактальная размерность D уменьшилась с 2,73 до 0,21.

При индексе однородности n=1, когда удельная площадь поверхности S увеличилась с 324 м²/кг до 405 м²/кг, фрактальная размерность D увеличилась с 2,28 до 2,36.

Кривая Фуллера, описывающая оптимальную упаковку, не может удовлетворить требованиям к распределению для различных диапазонов размеров частиц. Это приводит к образованию чрезмерно мелкого порошка. Мы можем заменить мелкие частицы менее 16 мкм и крупные частицы более 45 мкм активными добавками, например, золой или шлаковым порошком. Это увеличивает содержание ключевого диапазона (16, 45) мкм, который вносит наибольший вклад в прочность, оптимизирует распределение частиц по размерам и экономит цементный клинкер.

Мы предлагаем новую модель для первоначальной плотной упаковки частиц цемента: модель LH. Максимальный размер частиц в ней составляет 60 мкм, а минимальный - 0,6 мкм. Частицы размером менее 3 мкм не должны превышать 5%, а частицы в диапазоне (3, 32) мкм должны превышать 70%. Компьютерное моделирование показало, что у модели LH коэффициент пустотности составляет 27,9%. Она отвечает требованиям к производительности, сохраняя при этом низкую пористость.

04 Резюме

С развитием технологии помола качество цемента постепенно улучшается. Различные размеры частиц цемента определяют его применение. Расширение диапазона размеров частиц позволяет использовать их в зависимости от плотности, что подталкивает развитие цемента к новым тенденциям. Это создает больше возможностей для развития, способствует урбанизации и ускоряет прогресс. Следовательно, развитие технологии помола цемента продолжает широко применяться и использоваться.