The energy consumption of grinding system is the key index to measure its performance. At present, the grinding technology is developing in the direction of complete ball mill free system (such as vertical mill or roller press) and larger equipment. With the progress of cement technology, the total energy consumption of cement production shows the following trends:

- Ball Mill Era: Over 100 kWh/t

- Partial Bed Grinding Era: About 90 kWh/t

- Ball-Free Era: Below 80 kWh/t

This trend indicates that grinding technology is continuously improving to achieve lower energy consumption and higher production efficiency.

Methods to Reduce Energy Consumption in Ball Mill Systems

1. The Impact of Materials on Grinding System Energy Consumption

1.1 The Effect of Material Grindability

The yield of the cement grinding system closely relates to the grindability of clinker. The mineral composition and cooling rate of the clinker affect its grindability. For instance, clinkers with high C3S content and low C4AF content typically exhibit good grindability. Conversely, clinkers with high C2S and C4AF content lead to higher energy consumption. Therefore, optimizing the mineral composition and cooling conditions of clinker effectively reduces energy consumption.

1.2 The Impact of Material Particle Size

Reducing the feed particle size can significantly increase the mill output, thereby reducing energy consumption. When the average feed particle size is reduced from 30 mm to 2-3 mm, the mill output can be increased by more than 50%. In addition, the pre crushing process of “more crushing and less grinding” can effectively reduce excessive grinding and improve the efficiency of the mill.

1.3 The Impact of Material Temperature and Moisture

When the feed temperature exceeds 80 ℃, the internal temperature of the mill may exceed 120 ℃, resulting in reduced grinding efficiency and increased energy consumption. Therefore, controlling the clinker temperature and keeping the moisture content between 1.0% and 1.5% is very important to ensure the stable operation of the mill.

2. The Impact of Mill Ventilation on Energy Consumption

Strengthening the internal ventilation of the mill can reduce the buffer effect and increase the material flow rate, so as to reduce the temperature and increase the mill output. The air velocity inside the mill should be kept between 0.9 and 1.1 m/s to avoid excessive grinding and increased energy consumption. In addition, improving the system sealing to reduce air leakage is very important to reduce energy consumption.

3. Regular Maintenance and Inspection of the Mill

Regular inspection and maintenance of the mill, and optimization of ball loading, filling rate, sorting efficiency and other parameters are helpful to maintain system stability and high operation efficiency. Proper adjustment of the grinding body configuration is essential to achieve optimal mill performance.

4. The Impact of Particle Size Distribution on Product Quality and Energy Consumption

The optimal particle size distribution range of cement is 3 μ m to 32 μ m, and the content of fine particles is less than 10%. Regular analysis of particle size distribution is helpful to timely adjust ball loading of ball mill, improve mill efficiency and reduce energy consumption.

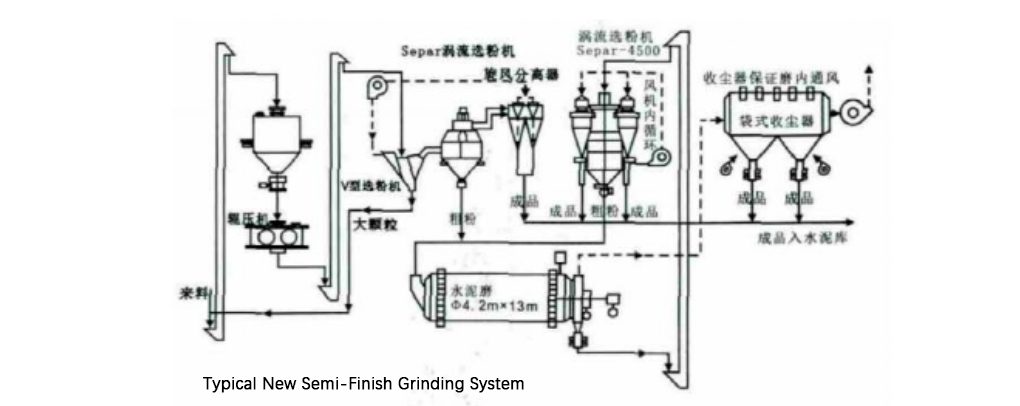

Optimization of Combined Grinding Systems

In the traditional combined grinding system, roller press and ball mill undertake different grinding tasks. By optimizing the management of ball mill, the energy consumption can be effectively reduced and the quality of cement can be improved.

- Advantages of the roller press: increase the working pressure of the roller press and significantly increase the output under stable operating conditions.

- Increase the total surface area of steel balls: adjust the diameter and number of steel balls to enhance the grinding capacity of the mill, so as to improve the grinding efficiency.

- Mill structure adjustment: shorten the rough grinding chamber, extend the effective length of the fine grinding chamber, and improve the fine grinding capacity of the mill.

Methods to Reduce Energy Consumption in Vertical Mill Systems

Vertical mill is a kind of grinding equipment with high efficiency and energy saving. Its energy consumption mainly comes from the autonomous motor and circulating fan. The following are suggestions for reducing the energy consumption of the vertical mill system:

1. Selection of Optimal Energy Parameters

The operator should adjust the operating parameters according to the trend of system parameters to achieve high production and low energy consumption.

2. Rational Use of System Airflow

Controlling the air flow of the mill to minimize air leakage can effectively reduce the energy consumption of the circulating fan.

3. Adjustment of the Material Retaining Ring

Regular inspection and adjustment of the height of the retaining ring can avoid low grinding efficiency due to improper thickness of the material layer.

4. Increasing Yield and Equipment Operating Rate

Ensure the continuous operation of the equipment, avoid unnecessary shutdown, help to improve stability and reduce energy consumption.

Conclusion

Every process and step in cement production holds potential for reducing energy consumption. By optimizing the grinding system comprehensively, we can significantly lower energy consumption, reduce production costs, and enhance market competitiveness. As professionals in the cement industry, mastering energy-saving technologies and management methods will contribute to achieving sustainable development goals.

For more information or inquiries, please feel free to contact us.