What Is a Bucket Elevator?

A bucket elevator is a continuous conveying machine that lifts materials vertically using a series of buckets evenly attached to an endless traction mechanism. The buckets are fixed to chains or belts and move materials upward in a vertical or near-vertical direction [1]. There are three types: ring chain, plate chain, and belt.

Darko provides professional bucket elevator solutions. We also produce explosion-proof bucket elevators compliant with the EU ATEX Directive. We ensure accurate selection and efficient conveying for your needs!

How a Bucket Elevator Works?

First, the buckets scoop material from the storage below. Then, the conveyor belt or chain lifts the buckets to the top. After passing over the top wheel, the buckets flip downward and discharge the material into the receiving chute.

Belt-driven bucket elevators use rubber belts mounted on drive pulleys (top or bottom) and redirecting pulleys.

Chain-driven bucket elevators use two parallel chains. Drive sprockets are at the top or bottom, and redirecting sprockets are at the opposite end.

Most bucket elevators have enclosures to prevent dust emissions.

Application: Moves materials from low to high positions. After loading via a vibrating table, the machine operates automatically for continuous upward transport.

Main Components

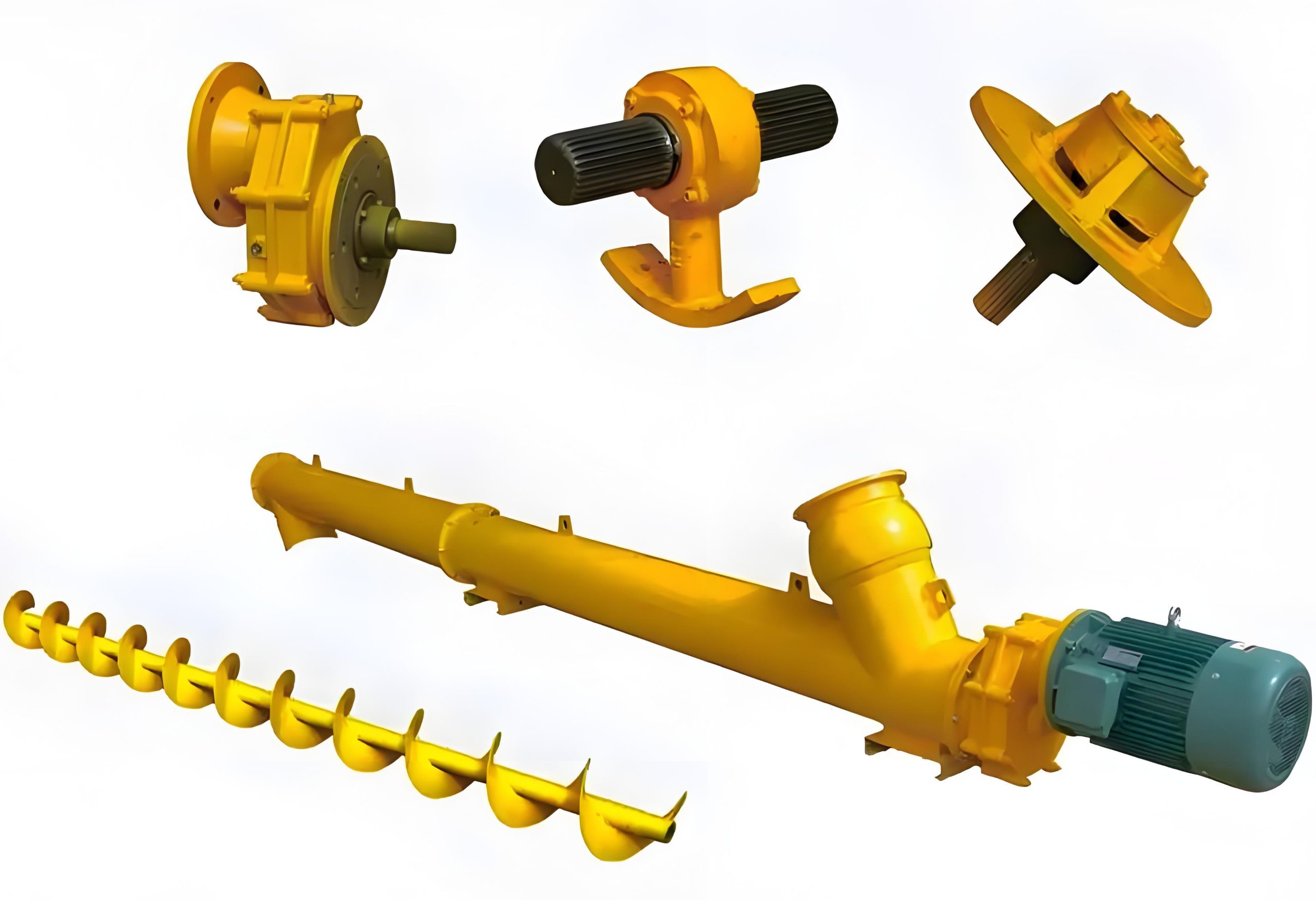

A bucket elevator consists of:

Buckets

Drive unit

Top and bottom pulleys (or sprockets)

Belt (or traction chain)

Tensioning device

Enclosure.

1. Traction Components

(1) Rubber Belt

Attached with screws and elastic washers.

Belt width is 35–40 mm wider than the bucket.

Standard belts handle materials ≤60°C; heat-resistant belts handle ≤150°C.

(2) Chains

Single chain: Fixed to the back of buckets (for widths of 160–250 mm).

Double chain: Connects to both sides of buckets (for widths of 320–630 mm).

Disadvantage: Chain joints wear easily, requiring frequent maintenance.

(3) Sprockets

Drive sprockets engage with chains to transmit motion.

Tooth design ensures smooth movement and reduces impact.

Heat-treated for strength and wear resistance.

2. Bucket Types

(1) Deep Cylindrical Buckets

Tilted opening, large depth.

Used for dry, free-flowing granular materials.

(2) Shallow Buckets

Tilted opening, small depth.

Used for wet or sticky granular materials.

Key Features

Bucket elevators offer:

Simple structure

Low maintenance

High efficiency

Stable operation

Wide application range

Advantages:

Low power consumption: Flow-through feeding and induced discharge reduce wasted energy.

Broad material compatibility: Handles powders, small particles, and abrasive materials with minimal dust.

High reliability: Advanced design ensures over 20,000 hours of trouble-free operation.

Long lifespan: Gentle material handling reduces wear and collisions.

Common Types

Bucket elevators are classified by transmission structure :

1. TD Series

Models: TD100 (rare), TD160, TD250, TD315, TD400, TD500, TD630, TD800, TD1000.

Widely used for general purposes.

2. TH Series

Uses forged ring chains for high strength.

Ideal for powders, small particles, and heavy materials.

Higher capacity and efficiency than TD series.

3. NE Series (Plate Chain)

Replaces older TB series.

Named by capacity (e.g., NE150 = 150 tons/hour).

Subtypes: NSE and high-speed models.

4. TG Series (Reinforced Belt)

Uses steel-reinforced belts for heavy-duty lifting.

Common in grain handling (“grain-dedicated bucket elevator”).

5. Other Models

HL (ring chain), GTD, GTH (variants of above).

Selection Guide

1. Discharge Methods

Centrifugal discharge (high speed): For powders and small particles.

Gravity discharge (low speed): For large, abrasive materials (e.g., limestone).

2. Traction Component Comparison

| Type | Pros | Cons | Max Temperature |

|---|---|---|---|

| Chain | Durable, simple | Heavy | 250°C |

| Plate | Lightweight, strong | Joint wear | 250°C |

| Belt | Simple | Not for abrasive materials | 60–120°C |

3. Selection Steps

Material type (powder/granular/lumps).

Properties (moisture, stickiness).

Bulk density (>1.6 requires special calculations).

Required capacity → Choose model → Confirm bucket type → Finalize.

Bucket Rule:

Powders: Shallow/curved buckets (centrifugal discharge).

Lumps: Deep buckets (gravity discharge).

Applications

- Cement Plant

- Grain Processing

- Chemical

- Pharmaceutical

- Mining

- Steel and Metal Processing

- Construction Materials

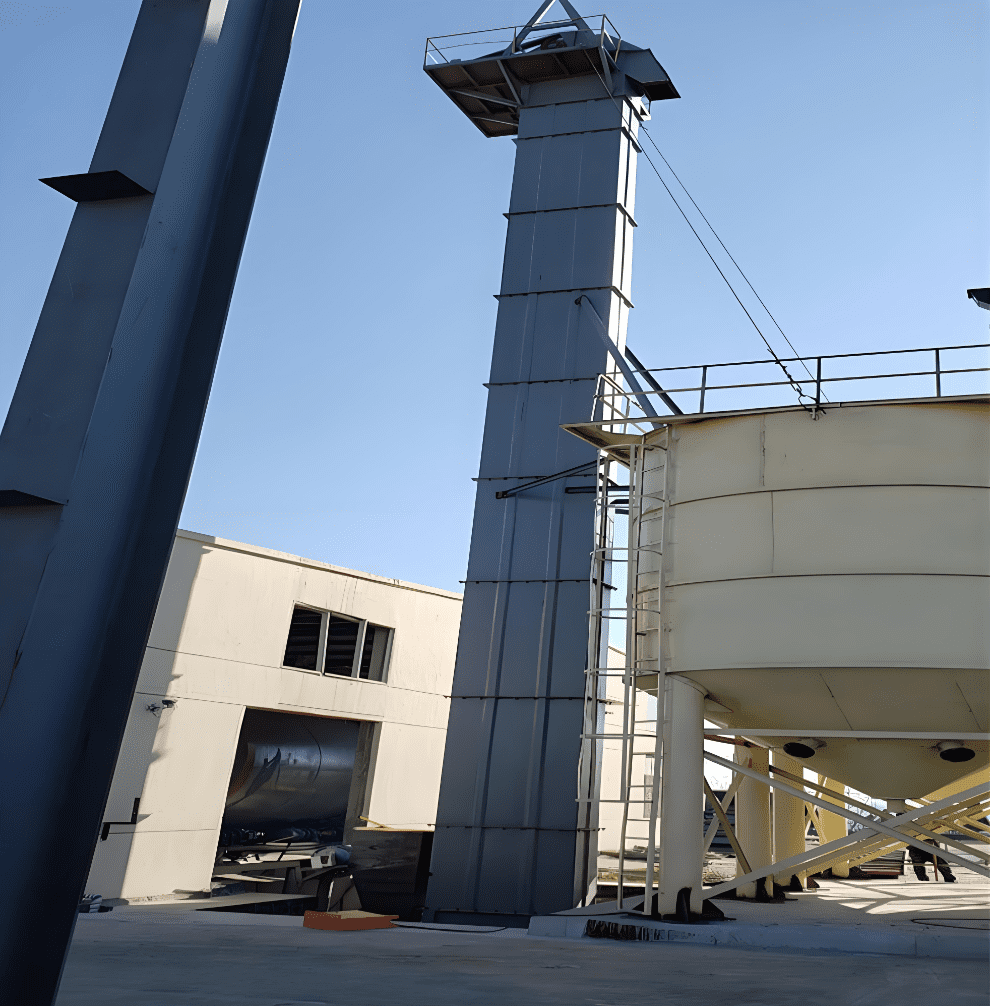

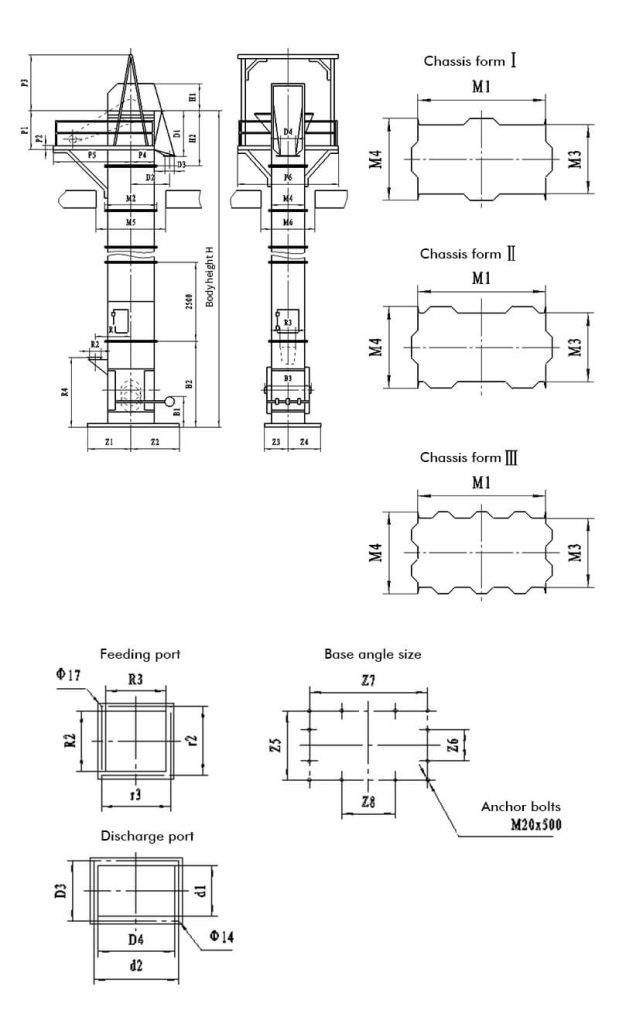

Appearance figure:

Need Help? Contact Darko for expert advice! Our engineers provide customized solutions and after-sales support to ensure optimal performance.

You May Also Like

|  |  |

|  |  |

Darko is among the fabric filters manufacturers in China. We have been supplying small and large companies with safe and ISO-certifed fabric filters wholesale. We provide industrial fabric filters of various specifications an custom sizes.

Darko has been working as a trust worthy fabric filter manufacturer and supplier in China for more than 10 years. With our years of experience in the industry, we can guarantee the production of high-quality Chinese fabric filters. Aside from manufacturing facilities in our own factory we also offer customization and design services to our customers. We produce fabric filters to process various air volume .

If you are looking for a filter company, you can rely on Darko. Buy fabric filters in bulk from us and let us help you grow your business using our customizable and affordable products.