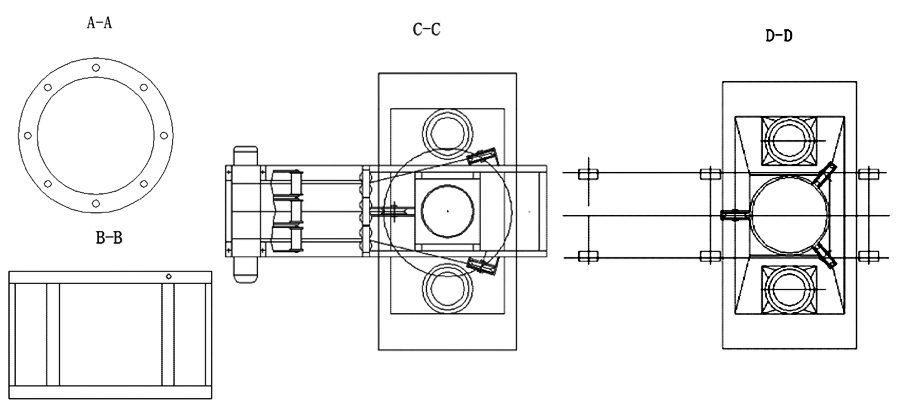

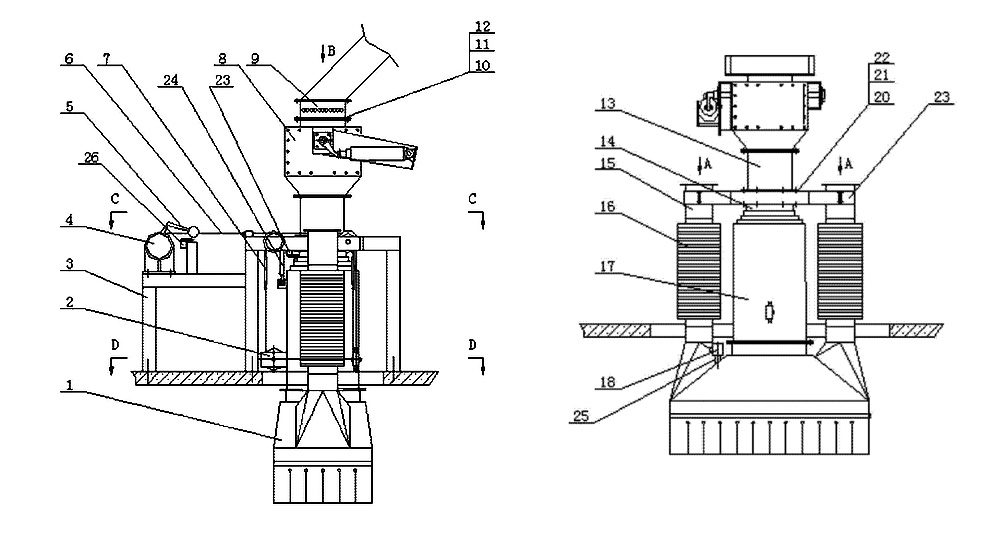

Drawing of clinker bulk loader

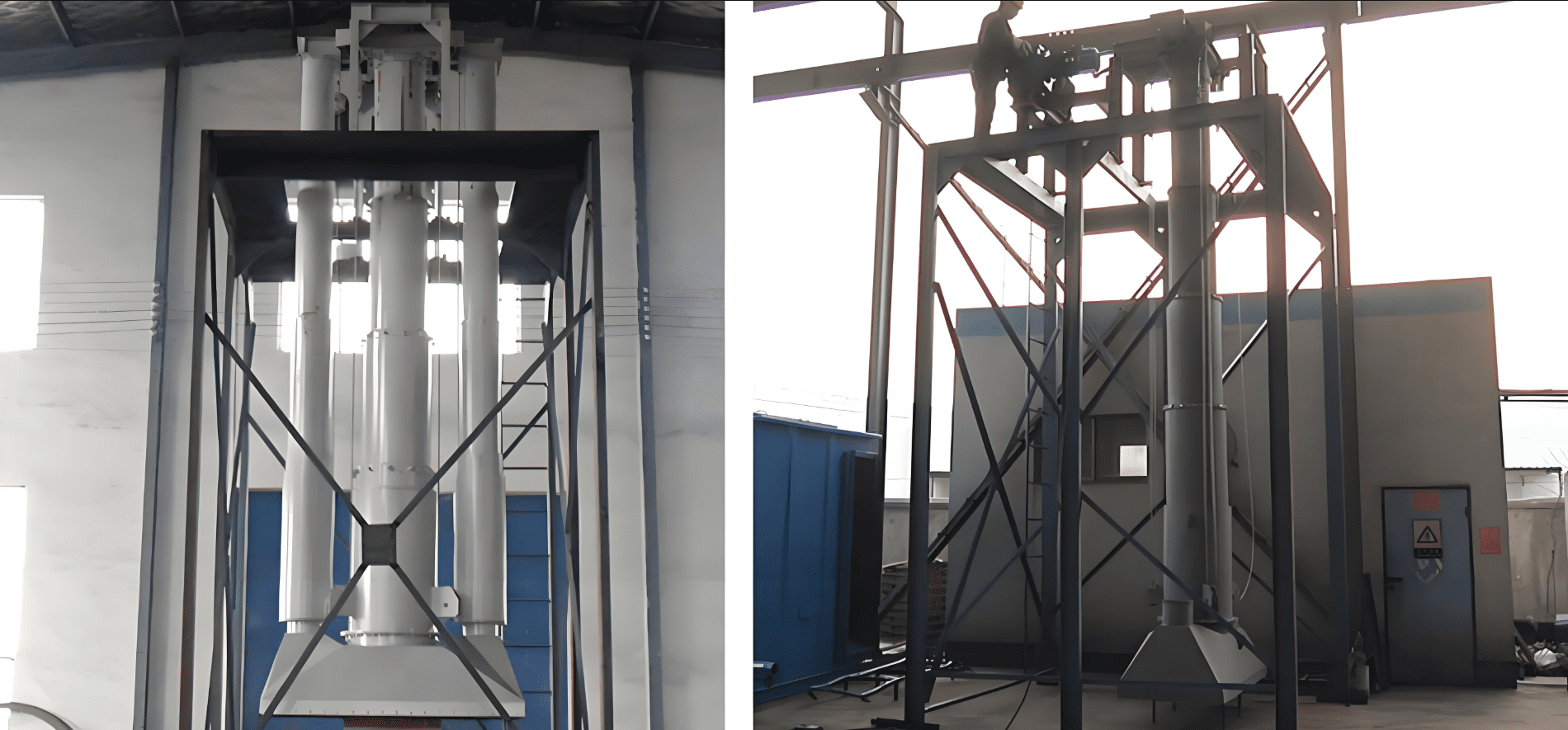

Darko‘s clinker bulk loader is an efficient and reliable equipment designed specifically for clinker loading in the cement industry.

The clinker bulk loader is a device that automatically transports clinker from the warehouse to clinker bulk trucks and ships.

The clinker bulk loader at the bottom of the warehouse is mainly composed of manual rod valves, electric (electro-hydraulic or pneumatic) fan valves, winches, telescopic unloading devices, dust collection hoses, capacitive limit switches, electronic control systems, etc.

Technical Data Sheet

| Technical performance | Technical Parameters | ||

| Conveying materials | Cement clinker or similar bulk materials | ||

| Material capacity | Clinker 1.45t/m³ | ||

| Material temperature | ≤150℃ | ||

| Material particle size | ≤50mm | ||

| Loading capacity | ≤300t/h | ||

| Discharge head telescopic distance | Customized according to user requirements | ||

| Manual stick valve | 790mm×790mm | 410mm×410mm | |

| Electric (pneumatic) sector valve | DZG1103 2×1.1KW | Electro-hydraulic push rod: DTY700-400/100 1.5KW (cylinder: QGB125×400-MP4) | |

| Hoist | CD1-18D Power: 3KW Lifting speed: 8M/S | ||

| Capacitive (tuning fork) limit switch | FTC131 probe specifications: φ25×400 Working pressure: 10bar Working temperature: -20℃~80℃ FTM31 probe specifications: φ20×230 lengthened 170mm Working pressure: 10bar | ||

| Installed power | ~5.2KW | ~4.5KW ( ~3KW) | |

| Reference drawing | SZT300-I/1 | SZT300- Ⅱ/2 | SSQ300-Ⅲ |

| Model | Kudi | Kudi | Side of warehouse |

Working principle

Loading Position Setup

When the transport vehicle enters the loading position, open the rod valve corresponding to the number of rods. This step is crucial for preparing the unloading process.

Activating the Unloading Head

Next, press and hold the “lowering button” on the control cabinet. After the unloading head is in place, the system will automatically disconnect the power of the elevator.

Entering Unloading State

To begin unloading, press the “loading button.” At this point, the auxiliary equipment will start working accordingly, facilitating the unloading process.

Dust Management During Unloading

The dust generated during unloading will pass through the unloading hopper. The telescopic dust collection hose will direct the dust into the dust collector for effective purification.

Monitoring Material Levels

When the material in the lower head is full, the lower head will rise while alarming. It is essential for the operator to set the rising distance before loading.

Setting Time Relay for Rising Distance

If the rising distance is 1 meter, ensure to set the time relay accordingly, adjusting it to T=1/V. During the rising process, charging will continue without interruption.

Repeating the Unloading Process

When the material is full, repeat the unloading process as described. After reaching the full position, press the stop button to reversely brake the electric vibrator or close the sector valve to halt discharging.

Final Steps After Parking

After parking, you can press the up button to keep the lower hopper away from the material at a certain distance. This ensures the displacement of the transportation tool before aligning it with the second unloading station.

Completing the Filling Process

Continue this procedure until the entire silo is filled. Proper management during the unloading process maximizes efficiency and minimizes dust emissions.

You may also like

|  |  |

|  |  |