What’s a ship loader?

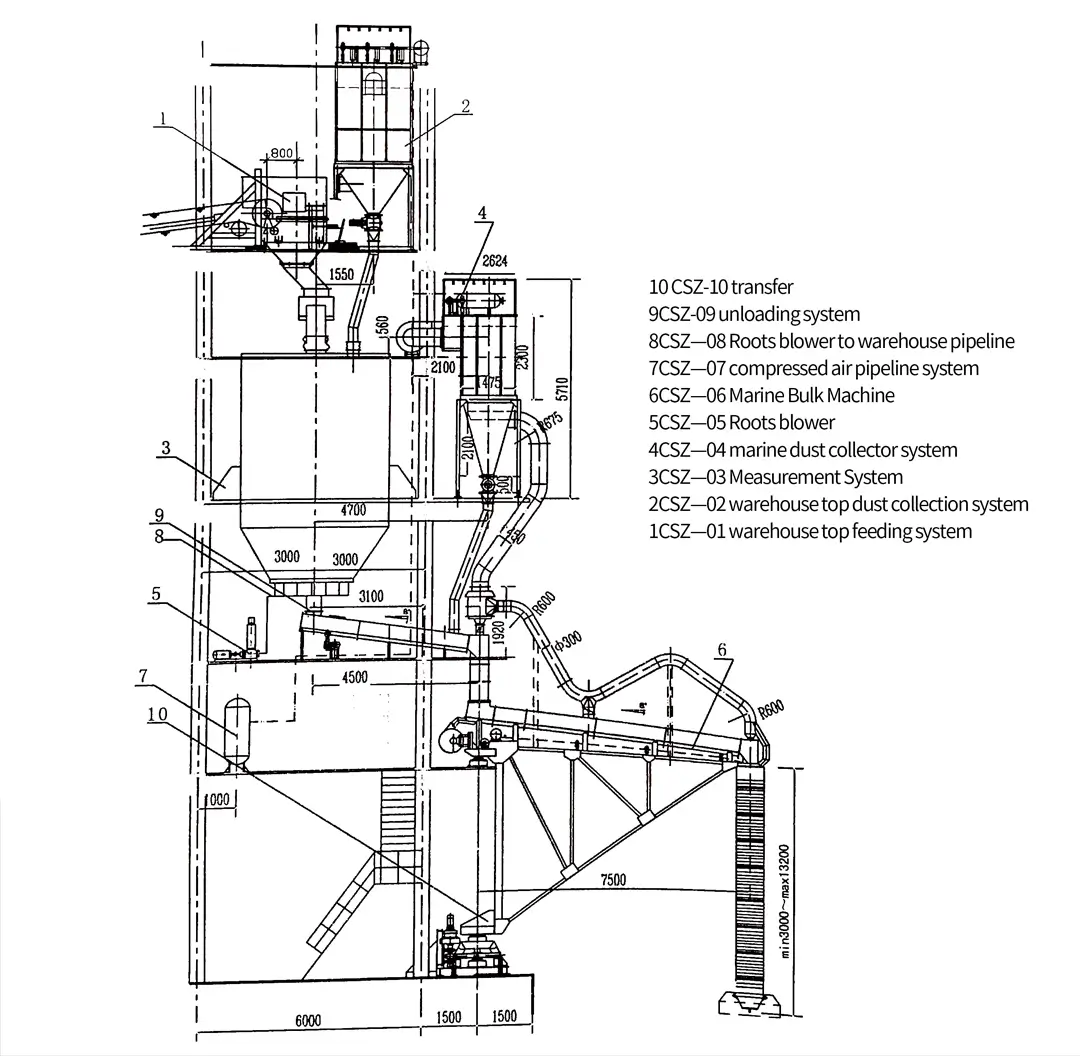

The ship loader is a machine that loads bulk and/or bagged solid materials onto ships for maritime transport. It is one of our reliable star products. Darko design solutions for the entire bulk cargo terminal. We will work closely with you to ensure our solutions meet your specific needs. Our high-capacity, high-efficiency un-loaders, loaders, conveyor systems, as well as stacking and reclaiming systems will save you a significant amount of costs by reducing operational time.

Application

Applied to: open bulk carriers, tankers, yards, etc

Material: powder, granular and block<300 mm

Type: Light type< 300 t/h, Heavy type >800 t/h, Stroke 2000~30000 mm,Customized engineering equipment for customers, with dust removal solutions.

Control: Automatically track the position of the ship and the height of the material pile, and can be equipped with an automatic distribution system

Why choose Darko’s ship loader?

High Automation: The ship loader for ships automates conveying, metering, loading, and monitoring, improving efficiency and accuracy while lowering manual labor costs and risks.

Large Capacity: It can be customized for loading capacities from hundreds to tens of thousands of tons, meeting various production needs.

Environmental Protection: Its closed loading system prevents dust and noise pollution during loading.

Strong Adaptability: A ship loader can adjust to different ship types and material characteristics, ensuring efficient and accurate loading.

Daily operation and maintenance

The operator of a ship loader should conduct a comprehensive inspection of the equipment 5-10 minutes before starting the machine. And then the operator should refuel and clean it according to the regulations. The last step is putting it into use after the test is correct.

During operation, the operator should strictly abide by the operating regulations and pay attention to the equipment at any time. If there are abnormalities or faults , the machine should be immediately shut down for inspection and eliminated in a timely manner.

You may also like

|  |  |

|  |  |