Os silos de pó são soluções de armazenamento industrial crítico utilizado para homogeneização de materiais, armazenamento a granel e equilíbrio da produção em sectores como cimento, transformação de alimentos, produtos químicos e farmacêuticos. No entanto, muitas empresas enfrentam desafios como baixa capacidade de armazenamento, fluxo de material deficiente, problemas de entupimento e sistemas de descarga ineficientesO que leva a atrasos na produção e a um aumento dos custos.

Neste guia, exploramos técnicas de otimização de silos de póincluindo redesenho do cone de descarga, melhorias na homogeneização do ar e sistemas de transporte avançados, para melhorar desempenho do silo, eficiência do fluxo de materiais e fiabilidade operacional.

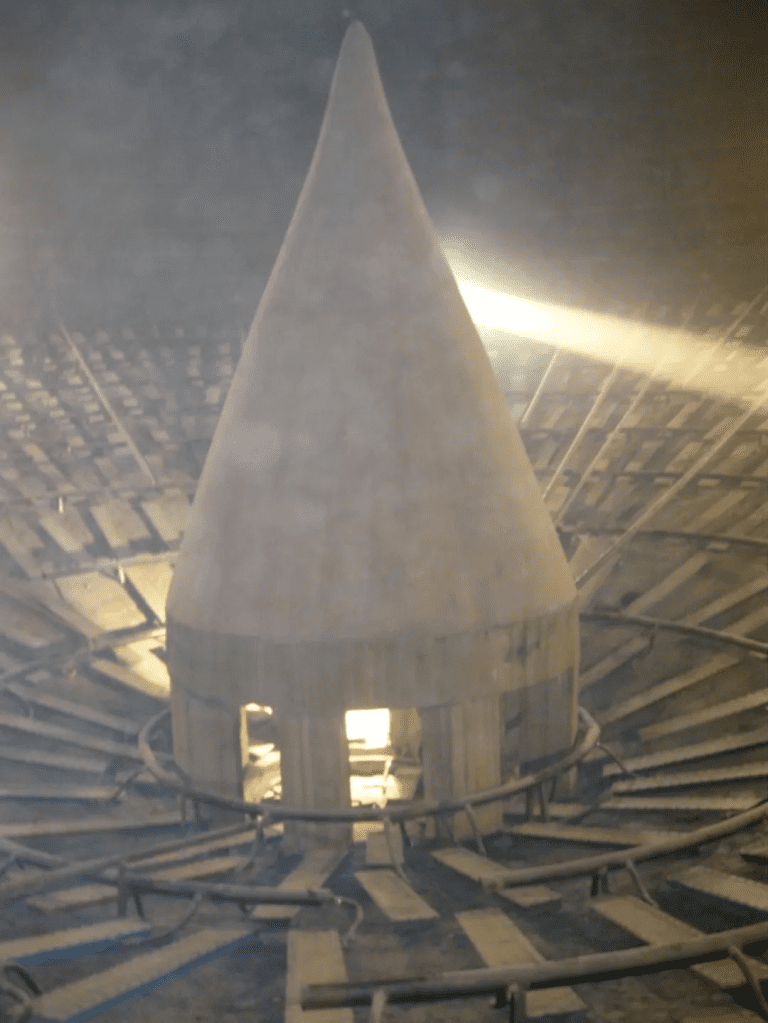

1. Otimização do cone de descarga para um melhor fluxo de material

Uma caraterística comum em silos de armazenagem de pó é o cone de descargaA sua estrutura é concebida para reduzir a pressão do material e facilitar um fluxo suave. No entanto, muitos silos continuam a registar entupimento, descarga irregular e controlo deficiente do fluxoespecialmente quando sistemas de arejamento estão inactivos.

Melhoria fundamental: Substitua os cones de descarga por válvulas de fluxo inteligentes

Problema: Os cones de descarga tradicionais muitas vezes não conseguem evitar ponte de material e fluxo irregular.

Resolve o problema: Instale um válvula de controlo de caudal de alta eficiência na saída do silo.

Monitorização da pressão em tempo real assegura um fluxo de material ótimo.

Abertura/fecho automatizado (semelhante aos travões ABS nos veículos) evita sobrepressurização e bloqueios de material.

Reduz os custos de manutenção e melhora fiabilidade da descarga do silo.

2. Homogeneização do ar: Mitos vs. Realidade

Muitos fabricantes acreditam que sistemas de homogeneização de ar misturar ativamente os materiais, mas o seu papel principal é garanta uma descarga consistentee não uma mistura forçada.

Como funciona realmente a homogeneização de silos

Homogeneização natural ocorre à medida que os materiais entram e saem do silo.

Sistemas de aeração prevenir principalmente compactação de materiais e esvaziamento de ratos.

Utilização excessiva da mistura de ar pode enfraquecer integridade estrutural do silo e aumentar o desperdício de energia.

Conselhos de manutenção para uma eficiência a longo prazo

Inspeccione regularmente almofadas de fluidificação e bocais de arejamento.

Limpe o interior dos silos para evitar acumulação de material e contaminação cruzada.

Optimize definições de pressão de ar para equilibrar velocidade de descarga e consumo de energia.

3. Escolher o melhor equipamento de descarga para silos de pó

O direito sistema de descarga de silos garante fluxo de material suave, dosagem precisa e tempo de inatividade reduzido. As opções mais comuns incluem:

A. Transportadores de corrediça de ar (de baixo custo mas limitados)

Prós: Acessível, eficiente em termos energéticos e à prova de pó.

Contras: Luta com materiais húmidos, aglomerados e pós abrasivos.

B. Transportadores de corrente de ar (alternativa superior)

Combina transportadores de corrente + tecnologia de deslizamento de ar para manuseamento de pó de alta eficiência.

Lida com materiais húmidos/aglomerados melhor do que os sistemas tradicionais.

Diminui a altura da fundação do silo, reduzindo custos de construção.

De acordo com principais empresas de engenharia de silos, mudando para transportadores de corrente de ar pode:

✔ Reduza os custos operacionais até 30%

✔ Melhore a fiabilidade do fluxo de materiais

✔ Reduza a frequência de manutenção

Conclusão: Optimize o seu silo de pó para um desempenho máximo

Atualização silos de armazenagem de pó com válvulas de fluxo inteligentes, arejamento optimizado e transportadores avançados pode aumente a eficiência, minimize o tempo de inatividade e prolongue a vida útil do equipamento.

Se tiveres alguma questão sobre a conceção de silos ou equipamento relacionado, não hesites em contactar-nos. Estamos a Darkoe nós estamos aqui para te dar apoio e soluções profissionais!