In the intricate world of bulk solids handling and pneumatic conveying systems, maintaining material flow while preventing unwanted air exchange, dust emissions, and contamination is a critical challenge. The válvula de aba dupla (DFV), also known as a double dump valve ou double flap airlock, stands out as an ingeniously simple yet highly effective solution designed specifically for these demanding tasks. This seemingly uncomplicated device plays a vital role in countless industrial processes by enabling reliable discharge of powders, granules, pellets, and other free-flowing materials while maintaining system pressure differentials and sealing integrity.

1. What is a Double Flap Valve?

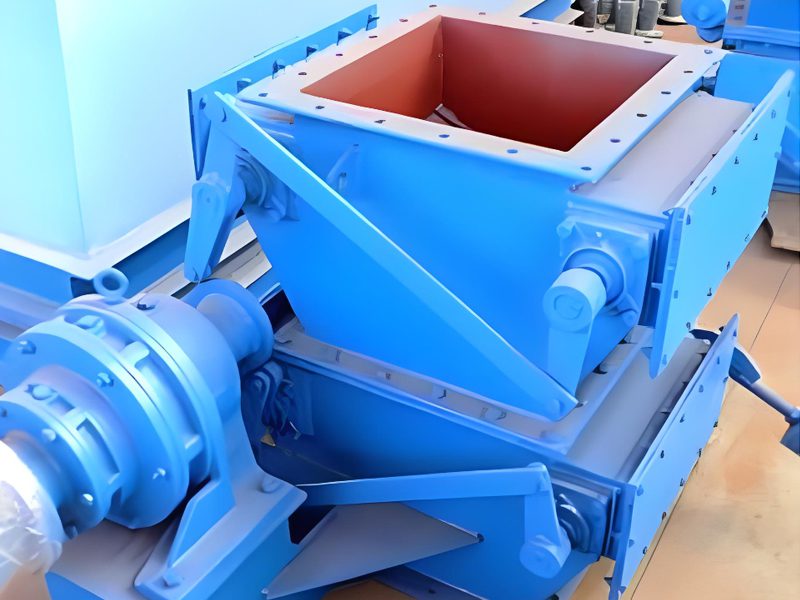

At its core, a double flap valve functions as an airlock and a discharge gate simultaneously. It’s essentially a two-stage gravity-operated valve installed beneath hoppers, silos, mixers, cyclones, or other process equipment. Its defining characteristic is the presence of two independently operated hinged flaps (doors or discs) arranged one above the other within a single housing. These flaps open and close in a carefully timed sequence, creating an intermediate “transfer chamber” that ensures material flows downwards while preventing gas (air, inert gases, or process gas) from traveling upwards or downwards uncontrollably. This makes DFVs indispensable for processes involving significant pressure differences across valves or strict containment requirements.

2. The Working Principle: A Simple Dance of Flaps

- Initial State (Both Closed): Both upper and lower flaps are sealed shut. Material accumulates above the closed upper flap.

- Upper Flap Opens (Material Fills Chamber): The upper flap actuator opens, allowing material to gravity-feed from the vessel above into the intermediate transfer chamber between the two flaps. The lower flap remains tightly closed, maintaining the seal against the lower pressure environment.

- Upper Flap Closes: Once the transfer chamber is filled (or after a preset time), the upper flap actuator closes and seals against the valve seat. This isolates the upstream vessel from the chamber.

- Lower Flap Opens (Material Discharges): With the upper flap sealed, the lower flap actuator opens, discharging the material from the transfer chamber into the downstream process (a conveyor, another vessel, a packaging line, etc.). Residual material clinging to the lower flap during opening is dislodged as it swings downwards.

- Lower Flap Closes: After the chamber empties (or after a preset time), the lower flap closes and seals against its seat, recreating the isolated transfer chamber. The upper flap can then open again to begin the next cycle.

This sequential operation creates a material “plug” within the transfer chamber. This plug acts as a barrier, effectively sealing the pressure differential between the inlet (e.g., a pressurized silo) and outlet (e.g., atmospheric conditions or a negative pressure system) while permitting controlled material flow. The speed of the cycle is typically adjustable to match the process feed rate.

3. Key Design Elements and Components

While variations exist, a typical double flap valve includes these essential parts:

- Housing/Valve Body: The robust frame holding the internal components. Often rectangular, but sometimes cylindrical. Features flanged connections (ANSI, DIN, etc.) at inlet and outlet. May include inspection windows, purge ports, or jacketing.

- Upper Flap: The inlet seal disk/door, hinged horizontally. First contact point for incoming material.

- Lower Flap: The outlet seal disk/door, hinged horizontally. Responsible for discharging material.

- Flap Seats: Precision-machined sealing surfaces mounted inside the housing. The flaps seal against these seats. Seat design is critical for leak-tightness and wear resistance.

- Actuators: Mechanisms driving flap movement. Common types include:

- Pneumatic Cylinders: Most common, offering simplicity, speed, and reliability. Can be spring-return (single-acting) or double-acting.

- Electric Actuators: Provide precise control and are well-suited for ATEX zones requiring no air supply. Gear motors or solenoids are used.

- Mechanical Lever Systems: Less common, sometimes driven by external machinery.

- Shafts & Bearings: Connect the flaps to the housing via sealed bearings. Must handle material abrasion and provide low-friction rotation. Shaft seals are critical.

- Transfer Chamber: The enclosed space between the flaps where the material accumulates temporarily. Size affects valve capacity and cycle speed.

- Control Unit (Optional): Timer relays, PLC interfaces, or proximity sensors to manage flap sequencing and interlocks (e.g., prevents upper flap opening if lower flap isn’t confirmed closed).

- Purge Connections (Optional): Ports for injecting air or inert gas to prevent material bridging, aid discharge, or maintain atmosphere integrity.

4. Materials of Construction: Matching the Application

Selecting the right materials is crucial for longevity and performance, depending heavily on the processed material:

- Alojamento: Mild steel (carbon steel, SS304/316), stainless steel (304, 316, 316L), abrasion-resistant steel (AR400/500), aluminum alloys. Often coated or lined with hard-facing alloys, polyurethane, or ceramic tiles for high abrasion applications.

- Flaps: Similar options to the housing. Often made from wear-resistant steel plates or fabricated stainless steel. May include replaceable sealing strips or wear plates.

- Seats: Critical wear surfaces. Machined from stainless steel, hard tool steel, or fitted with replaceable elastomeric seals (EPDM, Viton®, Silicone) for gas-tight seals in non-abrasive materials. Ceramic seat inserts offer extreme abrasion resistance.

- Shaft Seals: Lip seals, mechanical seals, or packing glands, often in PTFE, Viton®, or food-grade silicones. Prevent material ingress into bearings and gas leakage.

- Actuators: Aluminum, stainless steel, or coated/potting encapsulated for hazardous environments.

5. Why Choose a Double Flap Valve? Key Applications and Industries

DFVs excel in scenarios where simpler valves like slide gates or rotary valves fall short:

- Maintaining Pressure Differentials:

- Discharging from pressurized vessels/silos into atmospheric conditions.

- Feeding into negative-pressure pneumatic conveying systems.

- Maintaining inert atmospheres (e.g., nitrogen blanketing in reactors).

- Containment & Emissions Control:

- Preventing toxic dust emissions (process safety, environmental compliance).

- Containment of potent APIs in pharmaceuticals (OEB3/OEB4/5).

- Preventing moisture ingress into hygroscopic materials.

- Maintaining sterility in food/pharma processes.

- Handling Difficult Materials:

- Light, aeratable powders prone to flushing (e.g., flour, starch).

- Friable granules that degrade in rotary valve pockets.

- Materials prone to bridging/rat-holing (though design helps break minor bridges).

- Abrasive materials (when constructed appropriately).

- Industries Relying on DFVs:

- Chemical Manufacturing

- Food & Beverage (Flour, Sugar, Spices, Milk Powder)

- Pharmaceuticals & Biotechnology

- Plastics & Polymers (Pellets, Powder)

- Minerals & Mining (Ores, Sands, Cement)

- Power Generation (Biomass, Fly Ash)

- Ceramics & Glass

- Recycling & Waste Handling

6. Advantages and Disadvantages: A Balanced View

Vantagens:

- Excellent Sealing: Two independent seals provide high integrity against gas flow and dust leakage.

- Handles Pressure Differentials: Uniquely effective at operating under pressure gradients exceeding what rotary valves can manage.

- Good Flow Characteristics: Gravity discharge minimizes material degradation/deaeration. Handles a wide range of flow rates.

- Robust & Reliable: Few moving parts and simple principle translate to high reliability with proper maintenance.

- Minimal Blowback: The transfer chamber plug prevents significant air loss from pressurized systems.

- Containment Focus: Ideal for high-containment requirements.

- No External Lubrication: Sealed bearings eliminate points of contamination.

Desvantagens:

- Moving Parts & Wear: Flaps, seats, and seals are wear parts, especially critical in abrasive service. Regular inspection and replacement needed.

- No Continuous Discharge: Batch-wise operation (continuous plug flow occurs over multiple cycles) creates a pulsed discharge. Not ideal where smooth flow is mandatory.

- Size & Weight: Generally larger and heavier than comparable rotary valves for equivalent duty.

- Material Bridging: Can occur with cohesive materials above the top flap or in the chamber if design/activation isn’t optimized or material is very sticky. (Purge air/vibration can mitigate).

- Limited Capacity: Transfer chamber volume constrains the maximum per-cycle discharge quantity.

- No Product Shearing: While generally gentle, cohesive materials might form clumps that pass intact.

7. Selecting the Right Double Flap Valve: Critical Considerations

Choosing the optimal DFV requires evaluating numerous factors:

- Propriedades do material: Abrasiveness, bulk density, flowability (free-flowing, cohesive), particle size/shape, temperature, moisture content, toxicity, explosivity (ATEX/DSEAR ratings required?).

- Process Conditions: Operating pressures (positive/Negative differentials – max ΔP?), temperatures (ambient to high temp?), required discharge rate (kg/hr or lb/hr), required level of containment (leakage class?).

- Requisitos de vedação: Gas-tightness? Need for FDA/USP Class VI elastomers? Need for CIP/SIP?

- Connections: Flange size, type, and rating (ANSI, DIN, ASME, etc.) for inlet and outlet. Centerline height? Mounting constraints?

- Acionamento: Air supply available? Required cycle speed? Need for position feedback signals? Explosion-proof requirements? Reliability needs?

- Environmental/Safety: ATEX zone classification? Need for dust-tight? Need for grounding?

- Manutenção: Expected lifespan? Ease of seal/flap replacement? Available spares?

- Acessórios: Need for level probes above valve? Purge air fittings? Sight glasses? Insulation jacketing? Explosion venting?

- Cost: Balancing initial cost against total life-cycle cost (including maintenance and downtime).

Consulting manufacturers with extensive experience and providing detailed process data is crucial for correct sizing and specification.

8. Installation and Maintenance: Ensuring Longevity and Performance

Installation Best Practices: * Ensure adequate structural support for the valve’s weight and material load. * Level mounting is critical for proper flap sealing and gravity flow. Use shims if necessary. * Align inlet/outlet flanges precisely to avoid stress. Use proper gaskets. * Connect purge air lines tightly if used. * Ensure actuator air supply is clean, dry, and appropriately regulated (for pneumatic types). Verify electrical connections/earthing for electric types. * Commission interlocks/safety controls correctly. * Ensure smooth material flow into the valve inlet without obstructions.

Maintenance Essentials: * Regular Inspection: Visual checks for leaks, unusual sounds, or slow operation. Check actuator function and seals. * Seal & Wear Part Inspection/Replacement: Periodically inspect flap edges, seats, and shaft seals for wear, damage, or leaks. Replace proactively based on operating hours or material abrasiveness (key life-limiting parts). * Lubrificação: Follow manufacturer specs for sealed or non-lubricated bearings. Some shaft seal types might need occasional greasing. * Limpeza: Necessary during product changeovers (especially GMP environments) or after handling sticky materials. Follow cleaning procedures (manual wash-down or integrated CIP). * Torque Checks: Periodically check mounting bolt torque and flap hinge hardware. * Calibration (Optional Sensors): Ensure position sensors are calibrated if used. * Manutenção de registos: Document inspections and replacements for reliability analysis and compliance.

9. Conclusion: An Enduring Solution for Critical Transfers

The double flap valve is a workhorse engineered for a specific and vital purpose: enabling controlled material discharge under challenging pressure and containment conditions. Its simple yet effective alternating flap mechanism creates a reliable airlock barrier that rotary valves or slide gates struggle to match for integrity and pressure handling. While batch operation and wear potential are considerations, the DFV’s inherent advantages in sealing, versatility across demanding materials, and robust design make it an indispensable component in a vast array of industries. From ensuring the purity of life-saving pharmaceuticals to preventing explosions in grain silos or efficiently discharging cement into tankers, the double flap valve continues to provide a dependable and often essential sealing and transfer solution wherever bulk solids flow and pressure management are paramount. Careful selection, correct installation, and proactive maintenance are the keys to unlocking decades of reliable service from this fundamental process valve.