Problem: A stone powder company in Shanxi, China faced severe delays in bulk loading operations after installing a steel silo bulk loading system. Loading a single truck took 7-8 hours, drastically reducing production efficiency.

Despite trying common fixes—such as installing silo vibrators, air cannons, and fluidization nozzles—the issue persisted. The company reached out to Darko Machinery, a leading bulk material handling equipment manufacturer, for a professional solution.

Darko’s Expert Modifications for Faster Bulk Loading

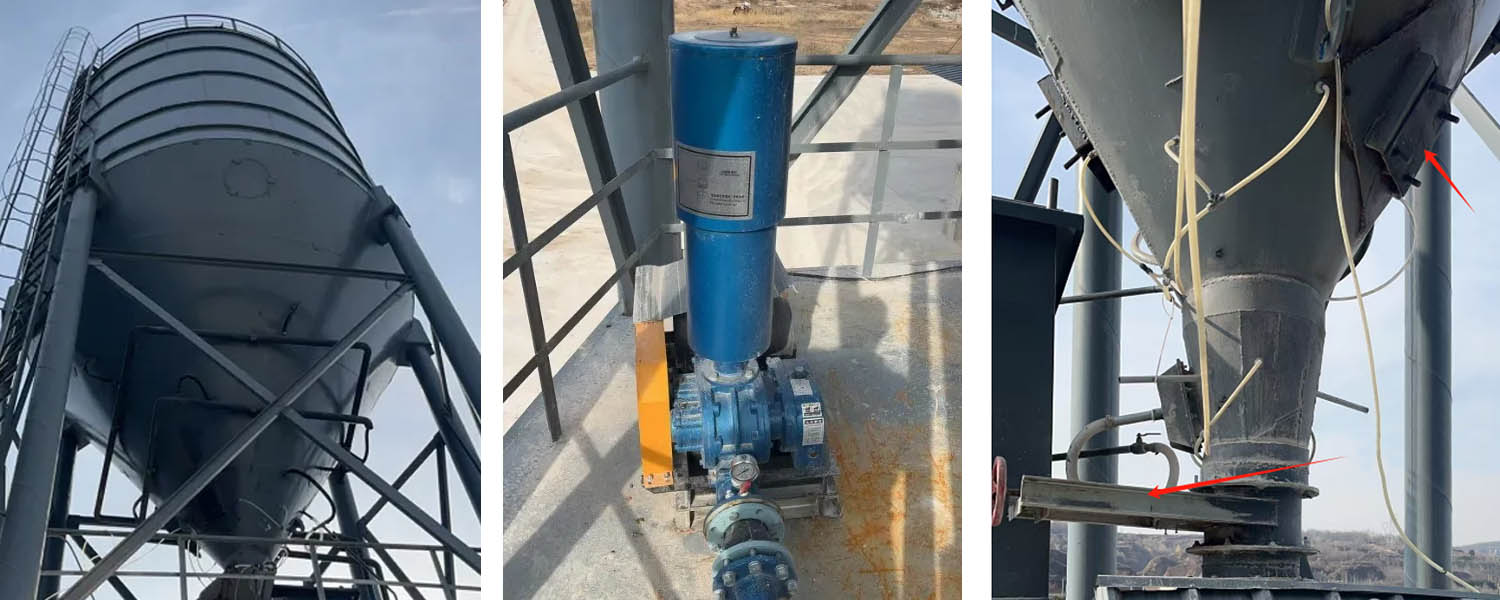

After analyzing the steel silo discharge system, we implemented three key improvements:

1. Installation of Zoned Air Supply Boxes

Replaced ineffective fluidization nozzles with targeted air supply boxes inside the silo cone.

Ensured even powder fluidization, preventing material clogging.

2. Switching from High-Pressure Air to Roots Blower

High-pressure air systems had low airflow + moisture, causing powder bridging & blockages.

Roots blower provided higher airflow, stable pressure, and moisture-free air—perfect for powder material fluidization.

3. Shortening the Vertical Discharge Pipe

Reduced material dead zones by minimizing the vertical pipe length between the silo cone and discharge gate.

Prevented powder compaction and improved continuous material flow.

Results: From 8 Hours to 10 Minutes per Truck!

After modifications, the stone powder loading speed improved dramatically:

✅ 10-minute loading time per truck (vs. 7-8 hours before)

✅ No more blockages or bridging in the silo

✅ Higher production capacity & ROI for the customer

Need a Reliable Bulk Material Handling Solution?

If your powder silo, cement storage, or bulk loading system suffers from:

Slow discharge rates

Material bridging & clogging

Inefficient fluidization

Contact Darko Machinery today!Get a free consultation & quote now!